Automatic counting and packing production line is delivered smoothly, and Hengli Packaging helps Wufangzhai zongzi packaging production

Release Date : 2022-11-18

One morning in November, the project team of Hengli Packaging began their busy delivery work.The equipment is dismantled, wrapped, packed, and transported to the long-awaited van. After a bumpy ride of several hours, the equipment is sent to Wufangzhai’s production workshop to help complete the difficult task of automatic counting and packing of zongzi.

With the rapid development of the food industry, Hengli Packaging has also decided to join the bureau and apply the rich experience of automatic packaging counting and packaging accumulated in the pharmaceutical industry to the field of food packaging. Help customers to improve the packaging level of products, enhance packaging creativity, so as to meet the growing personalized needs of consumers.

In the context of COVID-19: opportunities and challenges coexist

Although the current international situation is grim, and the production of domestic enterprises is often affected because of the repeated epidemic, it is both an opportunity and a challenge for Hengli Packaging. Hengli Packaging positions itself as an “expert in solving automated packaging problems”, and most of its target customers are suffering from the uncertainty caused by hiring workers. After all, not only does labor cost a lot of money, but workers’ sickness, vacation, and turnover can become important factors in the factory’s production schedule. This uncertainty is exacerbated by the current reality of containment and isolation.

So more and more enterprises are aware of the necessity of automated production, and Hengli packaging uphold the “want to users think, urgent users urgent” purpose of service, even during the epidemic also attracted customers from all walks of life to come to consult. Hengli Packaging and Wufangzhai have been in close contact since they got to know each other in Shanghai Exhibition. The zongzi counting and packing production line delivered this time has also helped them solve their urgent needs. We believe that this successful cooperation will encourage more enterprises who want to try to use intelligent devices for packaging production to feel the convenient charm of automatic packaging.

After equipment improvement: quality and efficiency together

Wufangzhai, as a well-known food enterprise, has a far-reaching brand influence in the country, so the control of product quality will naturally be more strict. The whole automatic packaging process is to pack different varieties of zongzi in boxes after identification and counting, requiring each box to pack 6, mixed packaging. The whole process seems simple, but every step has been carefully tested by Hengli Packaging research and development department and equipment department, which also encountered a lot of problems, but in front of the professional technical team all successfully resolved, in addition to create a lot of bright spots.

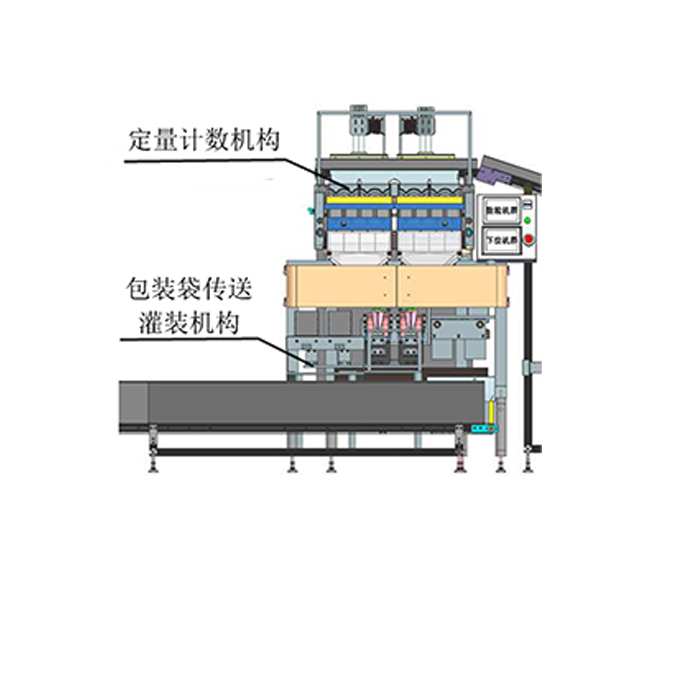

The production line is mainly composed of three machines, which are forming machine, several grain (zongzi) delivery machine and box loading machine, which is a rare organic combination of machine and production line.

In the beginning of the material management link, because of the special shape of zongzi is easy to cause accumulation, Hengli packaging elevator equipment through personalized improvement, so that the material becomes flexible and smooth, this problem is perfectly solved.Moreover, zongzi, as a large irregular material, is difficult to identify. However, the photoelectric sensor equipped with Hengli packaging can automatically identify any size, shape and texture of product materials, so zongzi is not a problem. Hengli Packaging is tailor-made for Wufangzhai, creatively using flexible support supply form, folding the packaging box into a tray, which is finally pushed into the folded box.The operation of a whole set of processes is fast and smooth, which not only effectively saves the space and labor applied to production, but also improves the speed, makes the operation safer, and significantly increases the overall benefit.

When looking to the future: Equal emphasis on solution and improvement

In this cooperation with Wufangzhai, Hengli Packaging’s modular machine design, cost-effective solutions and reliable operation of special products have been greatly recognized by partners, which also better implements Hengli Packaging’s action concept from managing products to managing customers and then gradually expanding to managing the industry.

In the future, we will continue to put the needs of customers in the first place, provide one-stop packaging problem solving ability, from the traditional business model to the real consumer demand as the center of business and organization model, use new technology, create new experience.

Automatic counting and packing production line is delivered smoothly, and Hengli Packaging helps Wufangzhai zongzi packaging production

Release Date : 2022-11-18

One morning in November, the project team of Hengli Packaging began their busy delivery work.The equipment is dismantled, wrapped, packed, and transported to the long-awaited van. After a bumpy ride of several hours, the equipment is sent to Wufangzhai’s production workshop to help complete the difficult task of automatic counting and packing of zongzi.

With the rapid development of the food industry, Hengli Packaging has also decided to join the bureau and apply the rich experience of automatic packaging counting and packaging accumulated in the pharmaceutical industry to the field of food packaging. Help customers to improve the packaging level of products, enhance packaging creativity, so as to meet the growing personalized needs of consumers.

In the context of COVID-19: opportunities and challenges coexist

Although the current international situation is grim, and the production of domestic enterprises is often affected because of the repeated epidemic, it is both an opportunity and a challenge for Hengli Packaging. Hengli Packaging positions itself as an “expert in solving automated packaging problems”, and most of its target customers are suffering from the uncertainty caused by hiring workers. After all, not only does labor cost a lot of money, but workers’ sickness, vacation, and turnover can become important factors in the factory’s production schedule. This uncertainty is exacerbated by the current reality of containment and isolation.

So more and more enterprises are aware of the necessity of automated production, and Hengli packaging uphold the “want to users think, urgent users urgent” purpose of service, even during the epidemic also attracted customers from all walks of life to come to consult. Hengli Packaging and Wufangzhai have been in close contact since they got to know each other in Shanghai Exhibition. The zongzi counting and packing production line delivered this time has also helped them solve their urgent needs. We believe that this successful cooperation will encourage more enterprises who want to try to use intelligent devices for packaging production to feel the convenient charm of automatic packaging.

After equipment improvement: quality and efficiency together

Wufangzhai, as a well-known food enterprise, has a far-reaching brand influence in the country, so the control of product quality will naturally be more strict. The whole automatic packaging process is to pack different varieties of zongzi in boxes after identification and counting, requiring each box to pack 6, mixed packaging. The whole process seems simple, but every step has been carefully tested by Hengli Packaging research and development department and equipment department, which also encountered a lot of problems, but in front of the professional technical team all successfully resolved, in addition to create a lot of bright spots.

The production line is mainly composed of three machines, which are forming machine, several grain (zongzi) delivery machine and box loading machine, which is a rare organic combination of machine and production line.

In the beginning of the material management link, because of the special shape of zongzi is easy to cause accumulation, Hengli packaging elevator equipment through personalized improvement, so that the material becomes flexible and smooth, this problem is perfectly solved.Moreover, zongzi, as a large irregular material, is difficult to identify. However, the photoelectric sensor equipped with Hengli packaging can automatically identify any size, shape and texture of product materials, so zongzi is not a problem. Hengli Packaging is tailor-made for Wufangzhai, creatively using flexible support supply form, folding the packaging box into a tray, which is finally pushed into the folded box.The operation of a whole set of processes is fast and smooth, which not only effectively saves the space and labor applied to production, but also improves the speed, makes the operation safer, and significantly increases the overall benefit.

When looking to the future: Equal emphasis on solution and improvement

In this cooperation with Wufangzhai, Hengli Packaging’s modular machine design, cost-effective solutions and reliable operation of special products have been greatly recognized by partners, which also better implements Hengli Packaging’s action concept from managing products to managing customers and then gradually expanding to managing the industry.

In the future, we will continue to put the needs of customers in the first place, provide one-stop packaging problem solving ability, from the traditional business model to the real consumer demand as the center of business and organization model, use new technology, create new experience.

HOT NEWS

HOT NEWS