Nearly 60% of vocational school graduates do not want to go to the factory? Hengli Packaging teaches you the ultimate solution

Release Date : 2022-06-30

Another year’s graduation season, a large number of fresh faces are about to leave the school and fly to a wider adult sky, while major companies are also waiting for the influx of fresh blood. Recently, however, a news has triggered a lot of discussion in all sectors of society: the headline “nearly 60% of vocational school students do not want to enter the factory after graduation” appeared on the front page of major online media, and people from all walks of life actively discussed it.

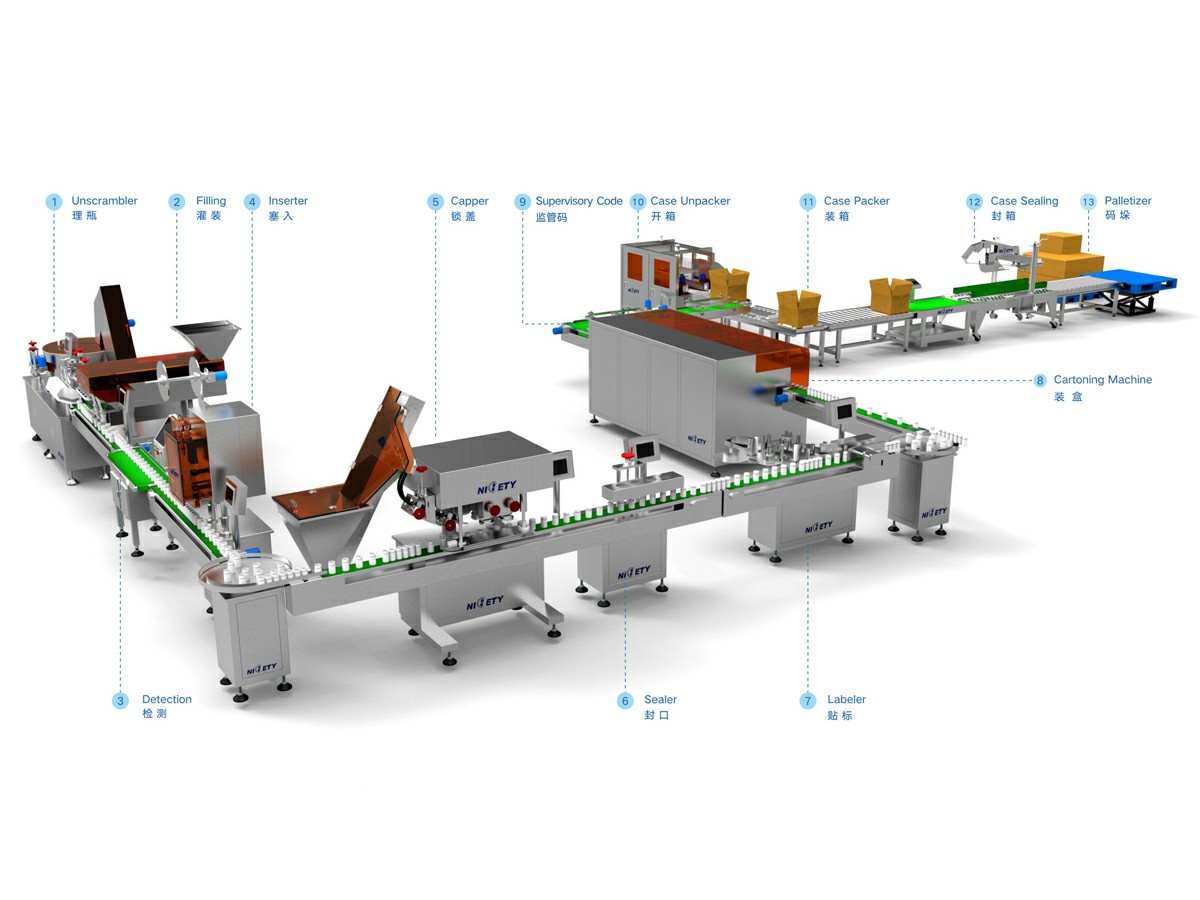

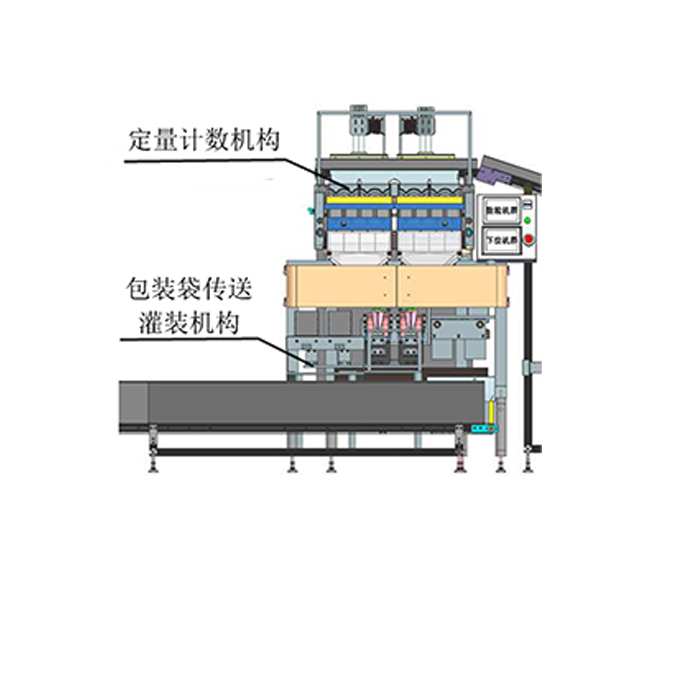

In fact, looking back at the intersection of the rapid development of manufacturing industry, the times have already undergone earth shaking changes, and today’s social phenomena similar to those mentioned above are also expected. Nowadays, with the rapid development of science and technology, most manufacturing enterprises have begun to introduce automatic equipment to replace manual production operations, and the ancient assembly line packaging mode is gradually being replaced by more convenient and efficient intelligent machinery. The upgrading of machines will certainly affect the working conditions of workers. For the practical application of machines, workers need to learn before they can formally put them into operation. It can be seen that automated machinery and workers are not absolute substitutes for each other, but complementary partners. Therefore, for young people who are about to enter the manufacturing industry, it is the right solution to actively adapt to the modern factory production mode.

McKinsey’s annual analysis report Skills Transformation in China: Promoting the World’s Largest Workforce to Become Lifelong Learners also pointed out that up to 220 million Chinese workers (accounting for 30% of the workforce) may change their careers due to the impact of automation technology by 2030. In the face of intuitive data, enterprises and practitioners are also experiencing a major transformation. At present, the packaging industry faces many problems, including but not limited to safety production, operating costs, market value orientation, etc. Since mechanized production packaging has become the trend, all of us need to do is to adapt to this social situation.

From the perspective of enterprises, how should we deal with various situations in the process of automation transformation?

In today’s environment of repeated epidemic situations, workers intensive enterprises may bear the risk of downtime due to infection at any time, and skilled labor is also a resource that is increasingly difficult to recruit and retain. In addition, various safety production accidents of workers also occur frequently. For these uncontrollable factors, enterprises will reduce a lot of burden by using intelligent driving efficiency innovation to create spiritual production after they switch to using automatic machines for corresponding alternative production packaging. Only in this way can the enterprise save a lot of costs, efficiently connect the supply and demand sides, put more energy into the product development and production stage, and create more market value for itself.

Since its inception, Hengli Packaging has been committed to helping enterprises solve various packaging problems. In recent years, it has keenly perceived the impact of the automation wave on various industries. As the core value of Hengli Packaging has always been to “think what users want, and rush what users want”, Hengli Packaging can quickly customize the scheme, develop corresponding equipment, and provide meticulous and thoughtful whole process services after deeply understanding the automated packaging needs of cooperative customers, so as to help everyone achieve maximum benefits.

For enterprises, it is wise to proceed from reality, follow the pace of the times, and strive to embrace automation. Hengli Packaging will always provide professional and competitive intelligent equipment to help any customer with automatic packaging needs to improve the packaging level.

Nearly 60% of vocational school graduates do not want to go to the factory? Hengli Packaging teaches you the ultimate solution

Release Date : 2022-06-30

Another year’s graduation season, a large number of fresh faces are about to leave the school and fly to a wider adult sky, while major companies are also waiting for the influx of fresh blood. Recently, however, a news has triggered a lot of discussion in all sectors of society: the headline “nearly 60% of vocational school students do not want to enter the factory after graduation” appeared on the front page of major online media, and people from all walks of life actively discussed it.

In fact, looking back at the intersection of the rapid development of manufacturing industry, the times have already undergone earth shaking changes, and today’s social phenomena similar to those mentioned above are also expected. Nowadays, with the rapid development of science and technology, most manufacturing enterprises have begun to introduce automatic equipment to replace manual production operations, and the ancient assembly line packaging mode is gradually being replaced by more convenient and efficient intelligent machinery. The upgrading of machines will certainly affect the working conditions of workers. For the practical application of machines, workers need to learn before they can formally put them into operation. It can be seen that automated machinery and workers are not absolute substitutes for each other, but complementary partners. Therefore, for young people who are about to enter the manufacturing industry, it is the right solution to actively adapt to the modern factory production mode.

McKinsey’s annual analysis report Skills Transformation in China: Promoting the World’s Largest Workforce to Become Lifelong Learners also pointed out that up to 220 million Chinese workers (accounting for 30% of the workforce) may change their careers due to the impact of automation technology by 2030. In the face of intuitive data, enterprises and practitioners are also experiencing a major transformation. At present, the packaging industry faces many problems, including but not limited to safety production, operating costs, market value orientation, etc. Since mechanized production packaging has become the trend, all of us need to do is to adapt to this social situation.

From the perspective of enterprises, how should we deal with various situations in the process of automation transformation?

In today’s environment of repeated epidemic situations, workers intensive enterprises may bear the risk of downtime due to infection at any time, and skilled labor is also a resource that is increasingly difficult to recruit and retain. In addition, various safety production accidents of workers also occur frequently. For these uncontrollable factors, enterprises will reduce a lot of burden by using intelligent driving efficiency innovation to create spiritual production after they switch to using automatic machines for corresponding alternative production packaging. Only in this way can the enterprise save a lot of costs, efficiently connect the supply and demand sides, put more energy into the product development and production stage, and create more market value for itself.

Since its inception, Hengli Packaging has been committed to helping enterprises solve various packaging problems. In recent years, it has keenly perceived the impact of the automation wave on various industries. As the core value of Hengli Packaging has always been to “think what users want, and rush what users want”, Hengli Packaging can quickly customize the scheme, develop corresponding equipment, and provide meticulous and thoughtful whole process services after deeply understanding the automated packaging needs of cooperative customers, so as to help everyone achieve maximum benefits.

For enterprises, it is wise to proceed from reality, follow the pace of the times, and strive to embrace automation. Hengli Packaging will always provide professional and competitive intelligent equipment to help any customer with automatic packaging needs to improve the packaging level.

HOT NEWS

HOT NEWS