Automatic packaging production reduces employment risk, Hengli Packaging uses intelligent manufacturing to write a new chapter of the times

Release Date : 2022-06-20

With the development of modern society and the continuous progress of science and technology, 5G era, intelligent manufacturing, and the use of automation to replace manual production operations have become commonplace in the manufacturing industry. Hengli Packaging has been committed to the research of intelligent production packaging equipment to solve the employment problems of enterprises, in order to help users improve productivity and product competitiveness in an all-round way. In order to make you more deeply understand the necessity of introducing automatic intelligent equipment, this paper will organize and analyze from multiple levels.

National level

Through the interpretation of the relevant policies issued in recent years, we can clearly feel that the burden of the enterprise itself has increased, so it is necessary to increase income and reduce expenditure in other aspects. Take the food industry as an example. It is undoubtedly a huge expense to hire people. It will also face many problems, such as standardized training of personnel, whether the operation is safe and proper, and unstable quality control. In addition, the current environmental problems are becoming increasingly serious, so enterprises need to pay more attention to these issues. In general, the above mentioned problems all indicate that the increase of employment costs will lead to the increase of uncontrollable risks. However, the introduction of automatic intelligent equipment can easily solve these problems.

Social dimension

Compared with the past employment and consumption situation, the current social structure and labor structure have undergone tremendous changes. The post-90s and post-00s have begun to leave the campus and enter the workplace. The new generation of young workers regard themselves as “migrant workers”, and their learning and growth environment is closely related to the development of the times. In the field of traditional manufacturing, the ancient artificial and large machine complex production mode is obviously no longer able to adapt to the working habits of these “newcomers”, so “simple and fast” has become the consensus of all work in modern society. When intelligent devices can help people to complete most of the packaging work, the existence and development of these devices will become inevitable.

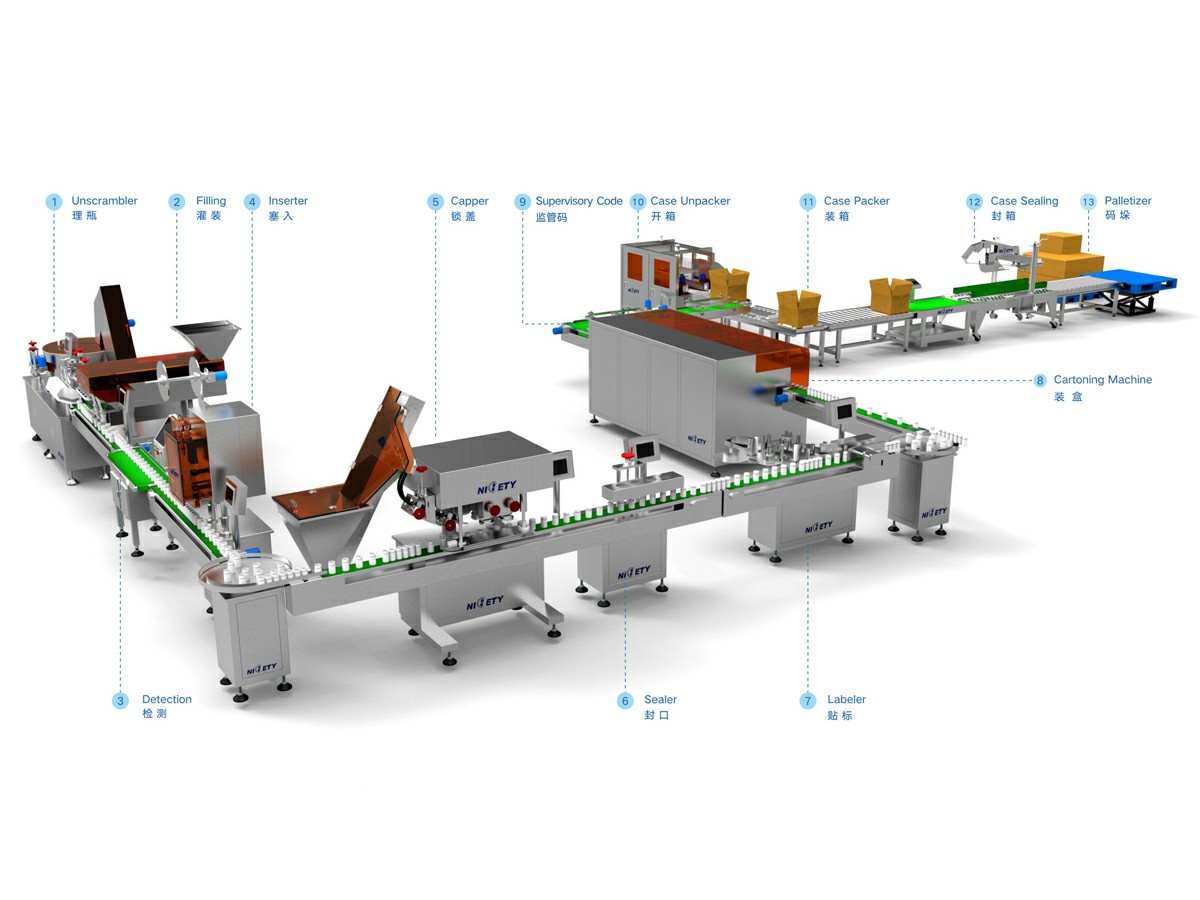

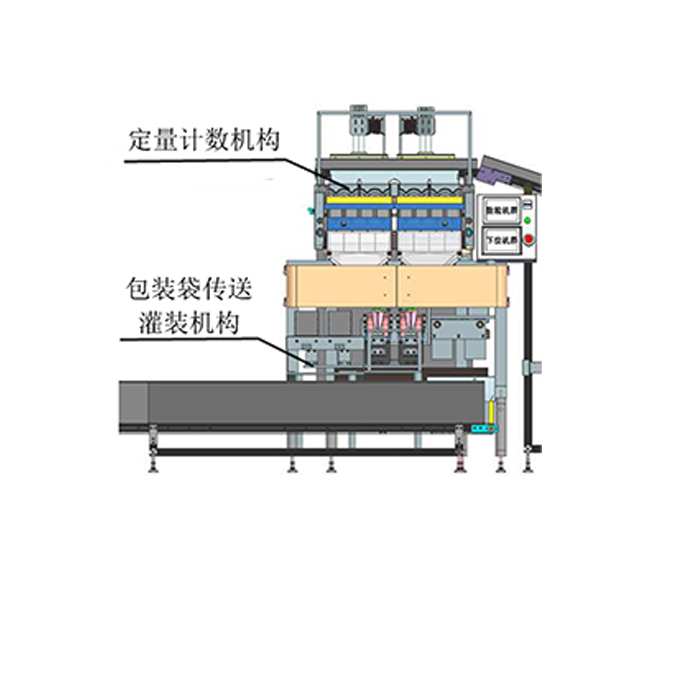

Technology adapted to the future: convenient (prefabricated) food mixed packaging production line

The concept of flexible intelligent packaging is introduced. Based on the analysis of the structural characteristics of the filling method and the user’s needs, the materials required by customers (candy, nuts or convenient prefabricated food) are sorted at a high speed according to the one-time packaging volume, integrated, sorted and combined, and automatically loaded into the same package through the large database and intelligent management system. Personalized information such as user name, name and quantity of the materials inside can be printed on the package to realize personalized flexible packaging of materials. This production line can be said to be a successful attempt for Hengli Packaging to set foot in intelligent production. In the face of the packaging mode that will increasingly highlight personality and life scenes in the future, it can fully realize more diversified packaging needs.

Enterprise level

Starting from the enterprise itself, manual participation in all aspects of packaging will increase many unnecessary risks. If we rely too much on manual work, we will have obvious disadvantages in the current environment of increased mobility of social personnel. With the rapid change of social needs, the speed of manual self renewal and improvement is far less than the upgrading speed of automatic intelligent equipment, let alone a series of tedious and time-consuming training processes. It is obviously that the cost performance of automatic equipment is higher. Enterprises must have a deep understanding in the recruitment process. The main contradiction at present is that human resources cannot meet the practical needs of society, which leads to a series of chain reactions. However, if intelligent equipment is used to replace manual production operations, these contradictions and problems will be solved.

With years of experience in researching intelligent automatic counting packaging equipment, Hengli Packaging has been fully aware of the core significance of scientific and technological innovation for enterprise development. At the same time, it also hopes to implement its own philosophy into specific operations. Relying on the modular production mode, Hengli Packaging has provided corresponding customized services from the product planning stage to ensure that packaging equipment All aspects of form and material selection can help customers reduce risks, improve production efficiency, and win a larger market. Hengli Packaging, the ability to provide one-stop solutions, has transformed the traditional business model into a truly customer-centric business and organizational model, applied new technology and created new experiences, providing a strong support for the transformation and upgrading of the manufacturing industry.

Automatic packaging production reduces employment risk, Hengli Packaging uses intelligent manufacturing to write a new chapter of the times

Release Date:2022-06-20

With the development of modern society and the continuous progress of science and technology, 5G era, intelligent manufacturing, and the use of automation to replace manual production operations have become commonplace in the manufacturing industry. Hengli Packaging has been committed to the research of intelligent production packaging equipment to solve the employment problems of enterprises, in order to help users improve productivity and product competitiveness in an all-round way. In order to make you more deeply understand the necessity of introducing automatic intelligent equipment, this paper will organize and analyze from multiple levels.

National level

Through the interpretation of the relevant policies issued in recent years, we can clearly feel that the burden of the enterprise itself has increased, so it is necessary to increase income and reduce expenditure in other aspects. Take the food industry as an example. It is undoubtedly a huge expense to hire people. It will also face many problems, such as standardized training of personnel, whether the operation is safe and proper, and unstable quality control. In addition, the current environmental problems are becoming increasingly serious, so enterprises need to pay more attention to these issues. In general, the above mentioned problems all indicate that the increase of employment costs will lead to the increase of uncontrollable risks. However, the introduction of automatic intelligent equipment can easily solve these problems.

Social dimension

Compared with the past employment and consumption situation, the current social structure and labor structure have undergone tremendous changes. The post-90s and post-00s have begun to leave the campus and enter the workplace. The new generation of young workers regard themselves as “migrant workers”, and their learning and growth environment is closely related to the development of the times. In the field of traditional manufacturing, the ancient artificial and large machine complex production mode is obviously no longer able to adapt to the working habits of these “newcomers”, so “simple and fast” has become the consensus of all work in modern society. When intelligent devices can help people to complete most of the packaging work, the existence and development of these devices will become inevitable.

Technology adapted to the future: convenient (prefabricated) food mixed packaging production line

The concept of flexible intelligent packaging is introduced. Based on the analysis of the structural characteristics of the filling method and the user’s needs, the materials required by customers (candy, nuts or convenient prefabricated food) are sorted at a high speed according to the one-time packaging volume, integrated, sorted and combined, and automatically loaded into the same package through the large database and intelligent management system. Personalized information such as user name, name and quantity of the materials inside can be printed on the package to realize personalized flexible packaging of materials. This production line can be said to be a successful attempt for Hengli Packaging to set foot in intelligent production. In the face of the packaging mode that will increasingly highlight personality and life scenes in the future, it can fully realize more diversified packaging needs.

Enterprise level

Starting from the enterprise itself, manual participation in all aspects of packaging will increase many unnecessary risks. If we rely too much on manual work, we will have obvious disadvantages in the current environment of increased mobility of social personnel. With the rapid change of social needs, the speed of manual self renewal and improvement is far less than the upgrading speed of automatic intelligent equipment, let alone a series of tedious and time-consuming training processes. It is obviously that the cost performance of automatic equipment is higher. Enterprises must have a deep understanding in the recruitment process. The main contradiction at present is that human resources cannot meet the practical needs of society, which leads to a series of chain reactions. However, if intelligent equipment is used to replace manual production operations, these contradictions and problems will be solved.

With years of experience in researching intelligent automatic counting packaging equipment, Hengli Packaging has been fully aware of the core significance of scientific and technological innovation for enterprise development. At the same time, it also hopes to implement its own philosophy into specific operations. Relying on the modular production mode, Hengli Packaging has provided corresponding customized services from the product planning stage to ensure that packaging equipment All aspects of form and material selection can help customers reduce risks, improve production efficiency, and win a larger market. Hengli Packaging, the ability to provide one-stop solutions, has transformed the traditional business model into a truly customer-centric business and organizational model, applied new technology and created new experiences, providing a strong support for the transformation and upgrading of the manufacturing industry.

HOT NEWS

HOT NEWS