COOKED EGG YOLK

01

Packaged form of cooked egg yolk

Eggs as an important daily diet side dish because of the rich nutrients, I believe that everyone is familiar with. Raw eggs are widely sold online and off, but what are the common uses of hard-boiled egg yolks? In fact, with the rise of baking and pet industries in recent years, the demand for cooked egg yolk is also increasing. Egg yolk crisp and pet freeze-dried snacks are the demand direction for cooked egg yolk, and their corresponding packaging forms are mostly vacuum packaging and canned.

Not long ago, Hengli Packaging also received inquiries about vacuum automatic packaging of cooked egg yolk. After understanding the basic information and packaging requirements of cooked egg yolk, Hengli Packaging, relying on years of experience in the automatic packaging industry, sends the materials sent by customers for trial testing, flexible counting equipment can fully meet the packaging needs of customers in terms of form and efficiency.

02

Technical equipment details

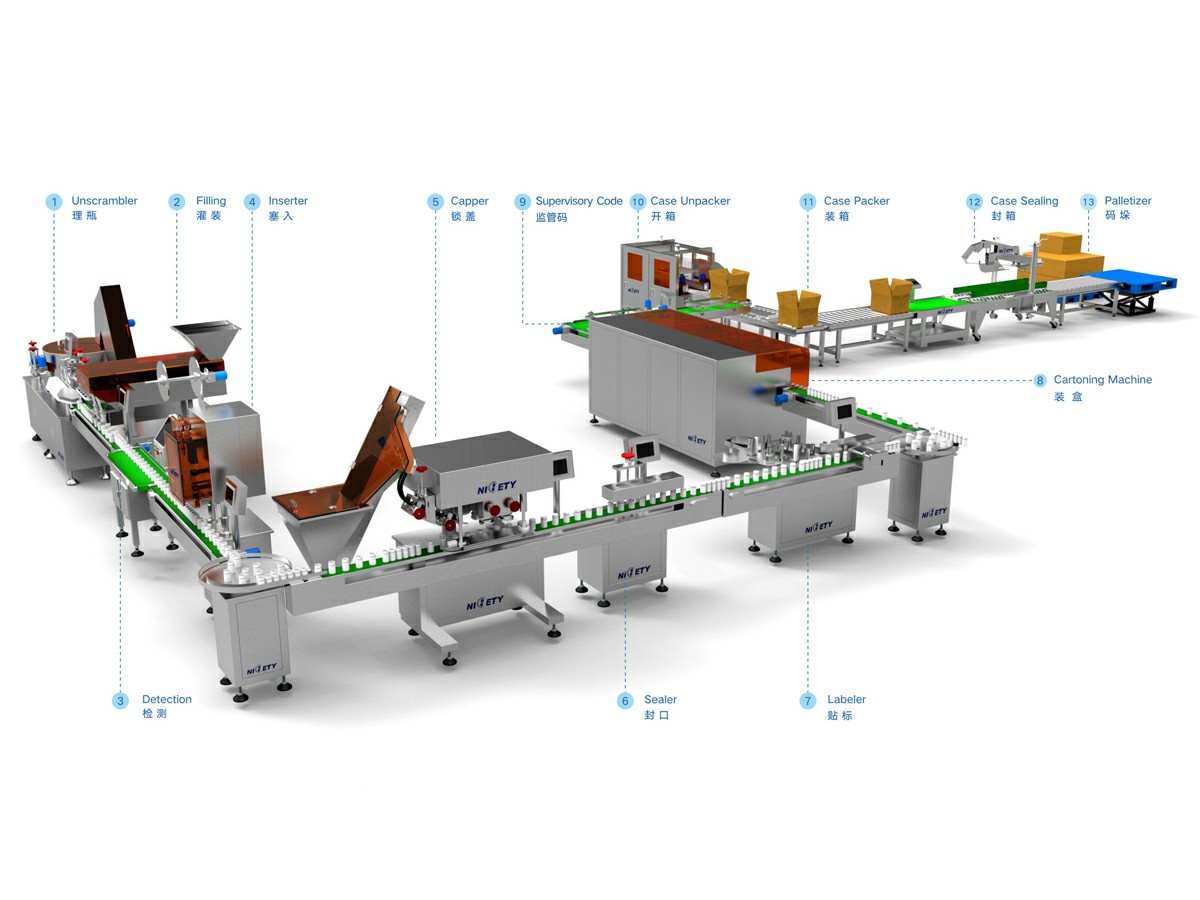

The production method of cooked egg yolk products on the market is mainly in the form of freeze-drying or baking dehydration, and the shape is relatively regular and easy to identify. But freeze-dried food needs to pay attention to adjust the amplitude on the vibration track, so as to avoid damage in the collision, and the surface of the dehydrated egg yolk is elastic, and the track amplitude is too large will also appear difficult to arrange the material. Hengli Packaging will customize personalized solutions for products of different textures, sizes, shapes and states, and can be flexibly connected with the front and back feeding, bagging and other equipment to form a complete packaging production line, to ensure the smooth and smooth process of packaging work.

03

Highlights of equipment packaging

- Equipment and materials in line with food safety and hygiene standards, waterproof and moisture-proof

- Efficient automation solves performance problems in the packaging process

- Precise robotics saves costs and improves efficiency

COOKED EGG YOLK

01

Packaged form of cooked egg yolk

Eggs as an important daily diet side dish because of the rich nutrients, I believe that everyone is familiar with. Raw eggs are widely sold online and off, but what are the common uses of hard-boiled egg yolks? In fact, with the rise of baking and pet industries in recent years, the demand for cooked egg yolk is also increasing. Egg yolk crisp and pet freeze-dried snacks are the demand direction for cooked egg yolk, and their corresponding packaging forms are mostly vacuum packaging and canned.

Not long ago, Hengli Packaging also received inquiries about vacuum automatic packaging of cooked egg yolk. After understanding the basic information and packaging requirements of cooked egg yolk, Hengli Packaging, relying on years of experience in the automatic packaging industry, sends the materials sent by customers for trial testing, flexible counting equipment can fully meet the packaging needs of customers in terms of form and efficiency.

02

Technical equipment details

The production method of cooked egg yolk products on the market is mainly in the form of freeze-drying or baking dehydration, and the shape is relatively regular and easy to identify. But freeze-dried food needs to pay attention to adjust the amplitude on the vibration track, so as to avoid damage in the collision, and the surface of the dehydrated egg yolk is elastic, and the track amplitude is too large will also appear difficult to arrange the material. Hengli Packaging will customize personalized solutions for products of different textures, sizes, shapes and states, and can be flexibly connected with the front and back feeding, bagging and other equipment to form a complete packaging production line, to ensure the smooth and smooth process of packaging work.

03

Highlights of equipment packaging

- Equipment and materials in line with food safety and hygiene standards, waterproof and moisture-proof

- Efficient automation solves performance problems in the packaging process

- Precise robotics saves costs and improves efficiency