STRENGTH EVIDENCE

STRENGTH EVIDENCE

Copy the core model of self heating hot pot“Hengli Packaging introduces the concept of flexibility to meet the personalized market demand”

Innovative R&D to solve customer problems on demand

At present, the market competition is becoming more and more fierce, and digital transformation has become an inevitable trend of industry development. Hengli Packaging has always kept pace with the development of the times, combined cutting-edge technology with consumer demand, innovatively developed convenient prefabricated food mixed packaging production line, integrated the concept of flexible intelligence, took simple operation and fast production as the starting point, based on the industry, to achieve customers’ personalized packaging needs.

The convenient prefabricated food mixed packaging production line, as an innovative equipment developed for the growing emphasis on personalized consumption, consists of three modules: the information layer, the management layer and the executive layer, covering the whole process from upstream information collection to midstream intelligent monitoring management to downstream customized packaging production. On the basis of analyzing the structural characteristics of the filling method and user needs, through the large database and intelligent management system, the materials required by customers (candy, nuts or convenient prefabricated food) can be quickly sorted, integrated, sorted and combined, and automatically loaded into the same package. Personalized information such as user name, name and quantity of the materials inside can be printed on the package to realize personalized flexible packaging of materials.

- When changing the packaging bag specification, automatically adjust the film setting mechanism, bag length parts, sealing and cutting parts and operating parameters according to the size.

- In terms of packaging form, it can not only measure and fill materials of a single variety, but also have the function of quantitative measurement of materials of multiple varieties and filling them into one packaging bag.

- On line monitoring of each mechanism or station of the machine can timely and accurately diagnose the abnormal working conditions of the machine and automatically repair.

- Intelligent management system, establishment and application of database, printing and storage, etc.

As for the popularity of self heating hot pot, daily nuts and other mixed foods in the consumer market, it is not difficult to find that grasping the diversified consumer demand has become the secret of hot selling products at present, but at the same time, the high cost and slow speed of manual packaging, and the difficulty in ensuring safe production and health conditions also need to be solved. When Hengli Packaging entered the food industry, it began to explore solutions to these difficulties. The mixed packaging production line for convenient prefabricated food developed by Hengli Packaging carried out product customization according to user preferences, combined the advantages of mixed packaging with personalized consumption needs, and realized information sharing in the front, middle and back ends relying on intelligent systems to promote the upgrading of the entire industrial chain.

- Innovative packaging mode combining four sets of four channel equipment

- Mixed packaging of various kinds of convenient fast food, customized recipes, and personalized consumption experience

- Human computer interaction page setting, parameter storage, intelligent operation, simple and fast

- Refine the concept of flexible packaging, expand consumption scenarios, and strive to integrate packaging technology into life

RECOMMENDED CASES

RELATED PRODUCTS

PARTNERS

Copy the core model of self heating hot pot “Hengli Packaging introduces the concept of flexibility to meet the personalized market demand”

Innovative R&D to solve customer problems on demand

Project background

At present, the market competition is becoming more and more fierce, and digital transformation has become an inevitable trend of industry development. Hengli Packaging has always kept pace with the development of the times, combined cutting-edge technology with consumer demand, innovatively developed convenient prefabricated food mixed packaging production line, integrated the concept of flexible intelligence, took simple operation and fast production as the starting point, based on the industry, to achieve customers’ personalized packaging needs.

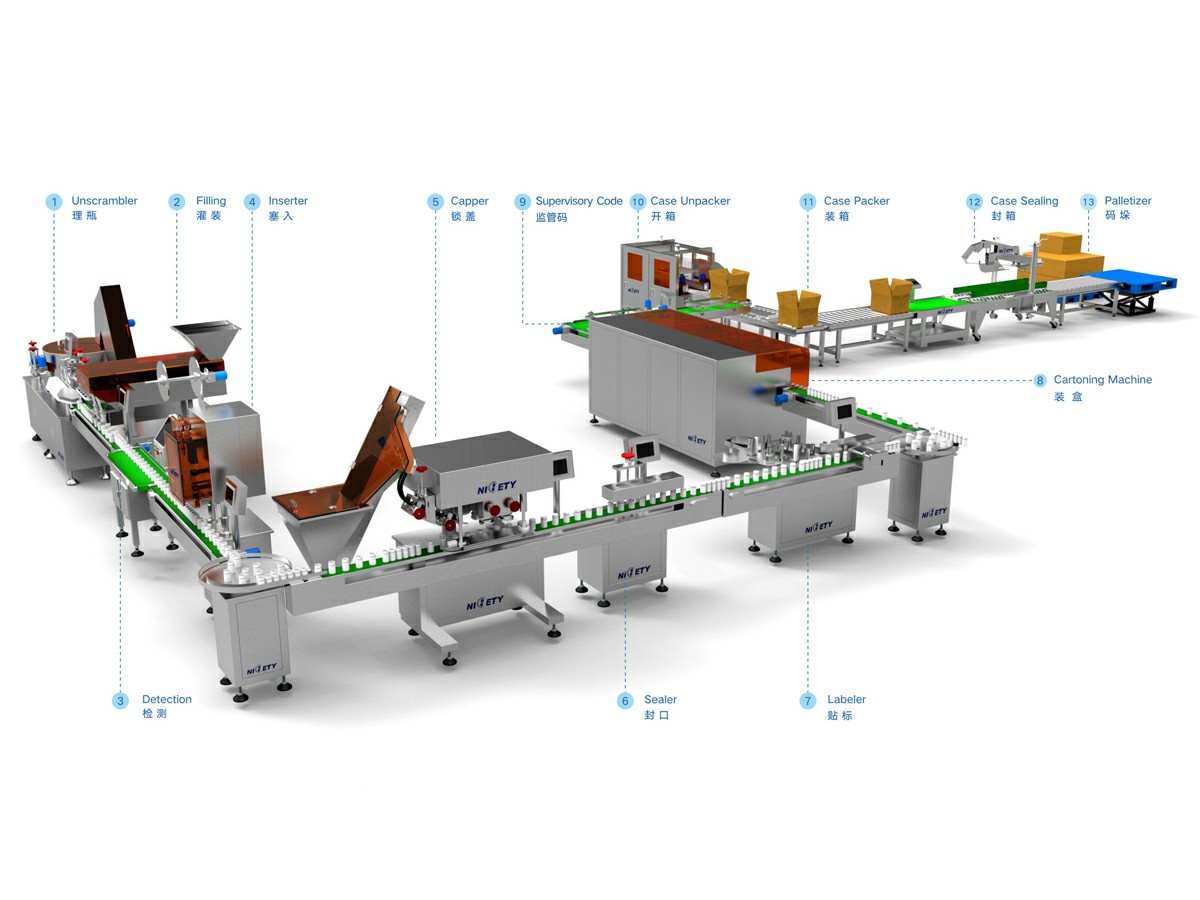

Composition of production line

The convenient prefabricated food mixed packaging production line, as an innovative equipment developed for the growing emphasis on personalized consumption, consists of three modules: the information layer, the management layer and the executive layer, covering the whole process from upstream information collection to midstream intelligent monitoring management to downstream customized packaging production. On the basis of analyzing the structural characteristics of the filling method and user needs, through the large database and intelligent management system, the materials required by customers (candy, nuts or convenient prefabricated food) can be quickly sorted, integrated, sorted and combined, and automatically loaded into the same package. Personalized information such as user name, name and quantity of the materials inside can be printed on the package to realize personalized flexible packaging of materials.

Technical highlights

- When changing the packaging bag specification, automatically adjust the film setting mechanism, bag length parts, sealing and cutting parts and operating parameters according to the size.

- In terms of packaging form, it can not only measure and fill materials of a single variety, but also have the function of quantitative measurement of materials of multiple varieties and filling them into one packaging bag.

- On line monitoring of each mechanism or station of the machine can timely and accurately diagnose the abnormal working conditions of the machine and automatically repair.

- Intelligent management system, establishment and application of database, printing and storage, etc.

Practical significance

As for the popularity of self heating hot pot, daily nuts and other mixed foods in the consumer market, it is not difficult to find that grasping the diversified consumer demand has become the secret of hot selling products at present, but at the same time, the high cost and slow speed of manual packaging, and the difficulty in ensuring safe production and health conditions also need to be solved. When Hengli Packaging entered the food industry, it began to explore solutions to these difficulties. The mixed packaging production line for convenient prefabricated food developed by Hengli Packaging carried out product customization according to user preferences, combined the advantages of mixed packaging with personalized consumption needs, and realized information sharing in the front, middle and back ends relying on intelligent systems to promote the upgrading of the entire industrial chain.

At a glance

- Innovative packaging mode combining four sets of four channel equipment

- Mixed packaging of various kinds of convenient fast food, customized recipes, and personalized consumption experience

- Human computer interaction page setting, parameter storage, intelligent operation, simple and fast

- Refine the concept of flexible packaging, expand consumption scenarios, and strive to integrate packaging technology into life