STRENGTH EVIDENCE

STRENGTH EVIDENCE

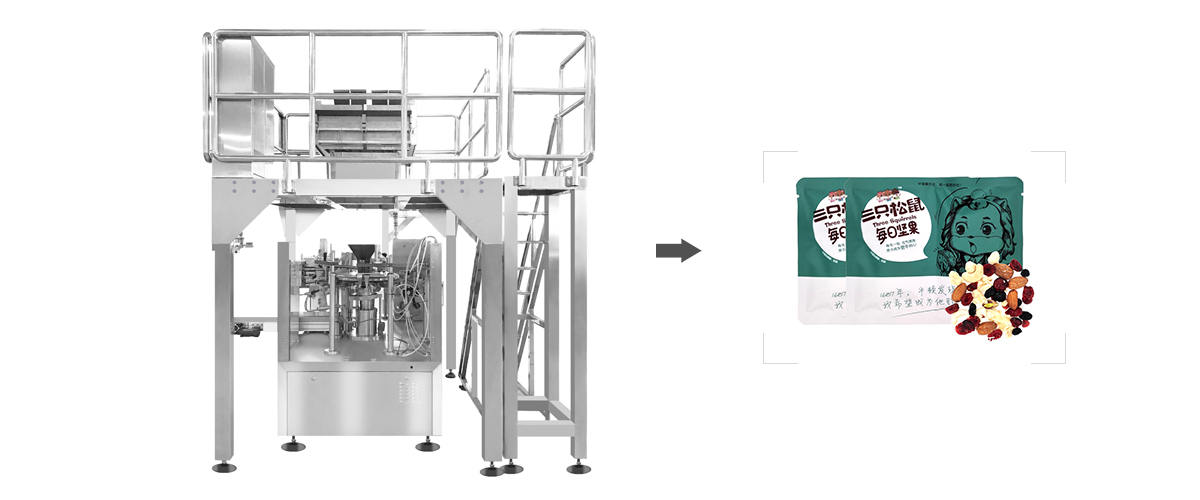

Hengli Packaging uses advanced technology to complete the counting and packaging of mixed nuts

Dry wet separation technology, effective coping strategies; Intelligent automatic equipment for efficient and stable packaging

In today’s food consumption market, the mixed nut snack products led by the three squirrels have attracted consumers of all ages to pay for them because of their healthy, natural and pollution-free selling points, and the “mixed nuts” category has become popular because of the warm pursuit.

With the popularity of mixed nuts, the new packaging form of mixing multiple varieties of nuts and dried fruits has attracted more and more attention from food manufacturers. Hengli’s daily mixed packaging production line of multiple varieties of nuts for several bags can fully meet the needs of automatic packaging, accurate counting, rapid and efficient batch production by relying on the automated packaging production mode, So as to help customers effectively improve the market competitiveness of mixed nut products.

- Dry wet separation technology, effective coping strategy

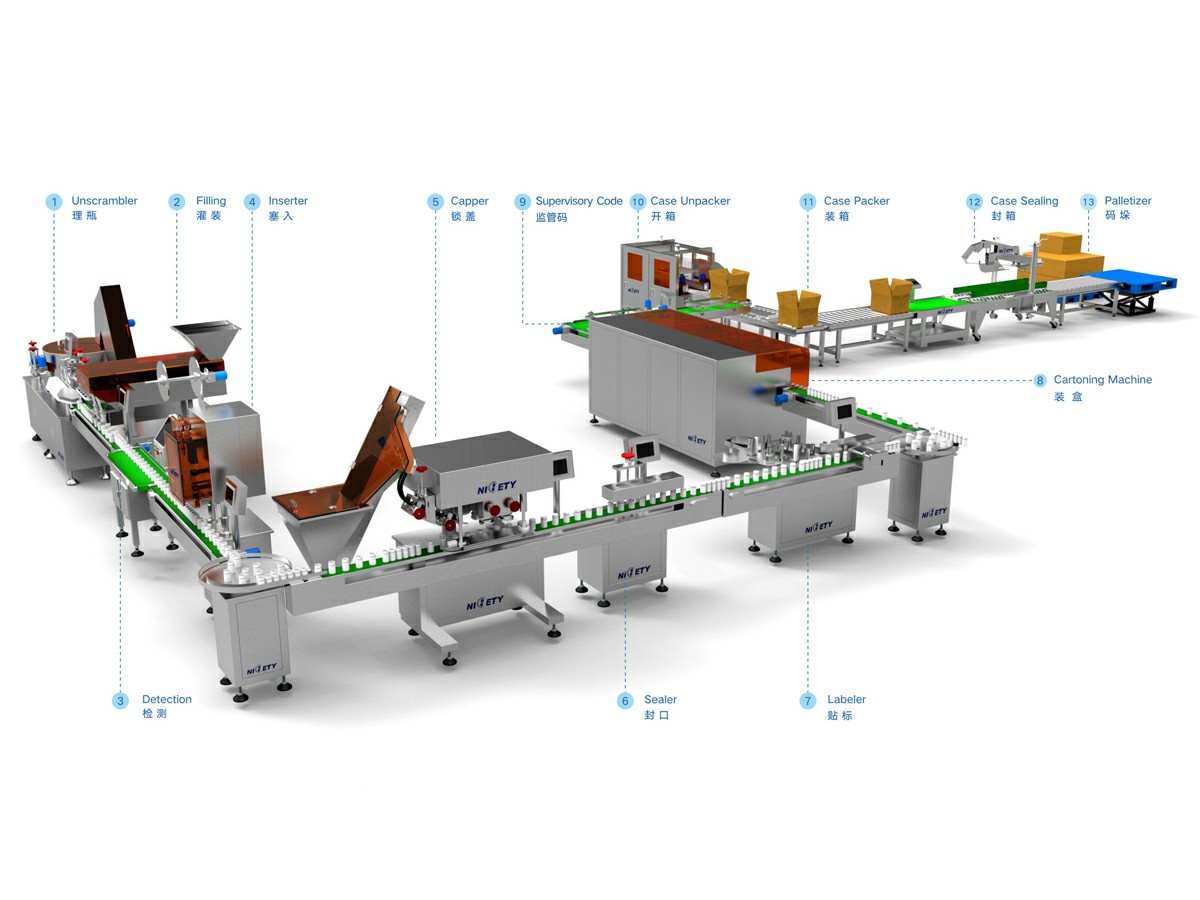

A major problem to be faced by the application of automatic intelligent equipment for mixed nut packaging is to separate the wet dried fruit from each other, which is basically difficult to achieve for manual packaging, but it becomes very easy on the multi-level vibration track of constant force packaging equipment. The track is designed and made of materials that meet the health standards of the food processing industry. It is waterproof and moisture-proof. Dried fruits such as cranberries can also be quickly separated and transported smoothly on the track.

- Intelligent automatic equipment for efficient and stable packaging

Hengli Packaging’s daily nut packaging equipment can solve the problem of separating dry and wet materials, which is the most troublesome for customers, and its performance in packaging speed and efficiency is also gratifying. In the face of the demand for large quantities of orders, the equipment can be packaged accurately and quickly according to the instructions, which can not only save a lot of time, but also save customers a considerable amount of cost without any remuneration.

- High degree of automation, simple and convenient operation

- Extend flexible packaging system to realize intelligent dry wet separation

- Accurately identify various material forms to meet diversified packaging requirements

For the packaging form of mixed nuts, the intelligent automatic equipment developed by Hengli Packaging can solve most of the problems. This technology also has great advantages in the current food packaging industry. As a newly emerging new packaging model, hybrid packaging provides a more convenient and personalized consumption experience in the consumer dimension. The cooperation between Hengli Packaging and the three squirrels will also lay a solid foundation for helping more enterprises to achieve their own needs in the future.

Hengli Packaging uses advanced technology to complete the counting and packaging of mixed nuts

Dry wet separation technology, effective coping strategies; Intelligent automatic equipment for efficient and stable packaging

Customer demand

In today’s food consumption market, the mixed nut snack products led by the three squirrels have attracted consumers of all ages to pay for them because of their healthy, natural and pollution-free selling points, and the “mixed nuts” category has become popular because of the warm pursuit.

With the popularity of mixed nuts, the new packaging form of mixing multiple varieties of nuts and dried fruits has attracted more and more attention from food manufacturers. Hengli’s daily mixed packaging production line of multiple varieties of nuts for several bags can fully meet the needs of automatic packaging, accurate counting, rapid and efficient batch production by relying on the automated packaging production mode, So as to help customers effectively improve the market competitiveness of mixed nut products.

Terms of settlement

- Dry wet separation technology, effective coping strategy

A major problem to be faced by the application of automatic intelligent equipment for mixed nut packaging is to separate the wet dried fruit from each other, which is basically difficult to achieve for manual packaging, but it becomes very easy on the multi-level vibration track of constant force packaging equipment. The track is designed and made of materials that meet the health standards of the food processing industry. It is waterproof and moisture-proof. Dried fruits such as cranberries can also be quickly separated and transported smoothly on the track.

- Intelligent automatic equipment for efficient and stable packaging

Hengli Packaging’s daily nut packaging equipment can solve the problem of separating dry and wet materials, which is the most troublesome for customers, and its performance in packaging speed and efficiency is also gratifying. In the face of the demand for large quantities of orders, the equipment can be packaged accurately and quickly according to the instructions, which can not only save a lot of time, but also save customers a considerable amount of cost without any remuneration.

At a glance

- High degree of automation, simple and convenient operation

- Extend flexible packaging system to realize intelligent dry wet separation

- Accurately identify various material forms to meet diversified packaging requirements

Future outlook

For the packaging form of mixed nuts, the intelligent automatic equipment developed by Hengli Packaging can solve most of the problems. This technology also has great advantages in the current food packaging industry. As a newly emerging new packaging model, hybrid packaging provides a more convenient and personalized consumption experience in the consumer dimension. The cooperation between Hengli Packaging and the three squirrels will also lay a solid foundation for helping more enterprises to achieve their own needs in the future.