STRENGTH EVIDENCE

STRENGTH EVIDENCE

For the current popular snack cheese bar“Hengli Packaging Realizes Intelligent Mixed Counting Packaging”

Intelligent multi grain bagging technology to meet the demand of food market

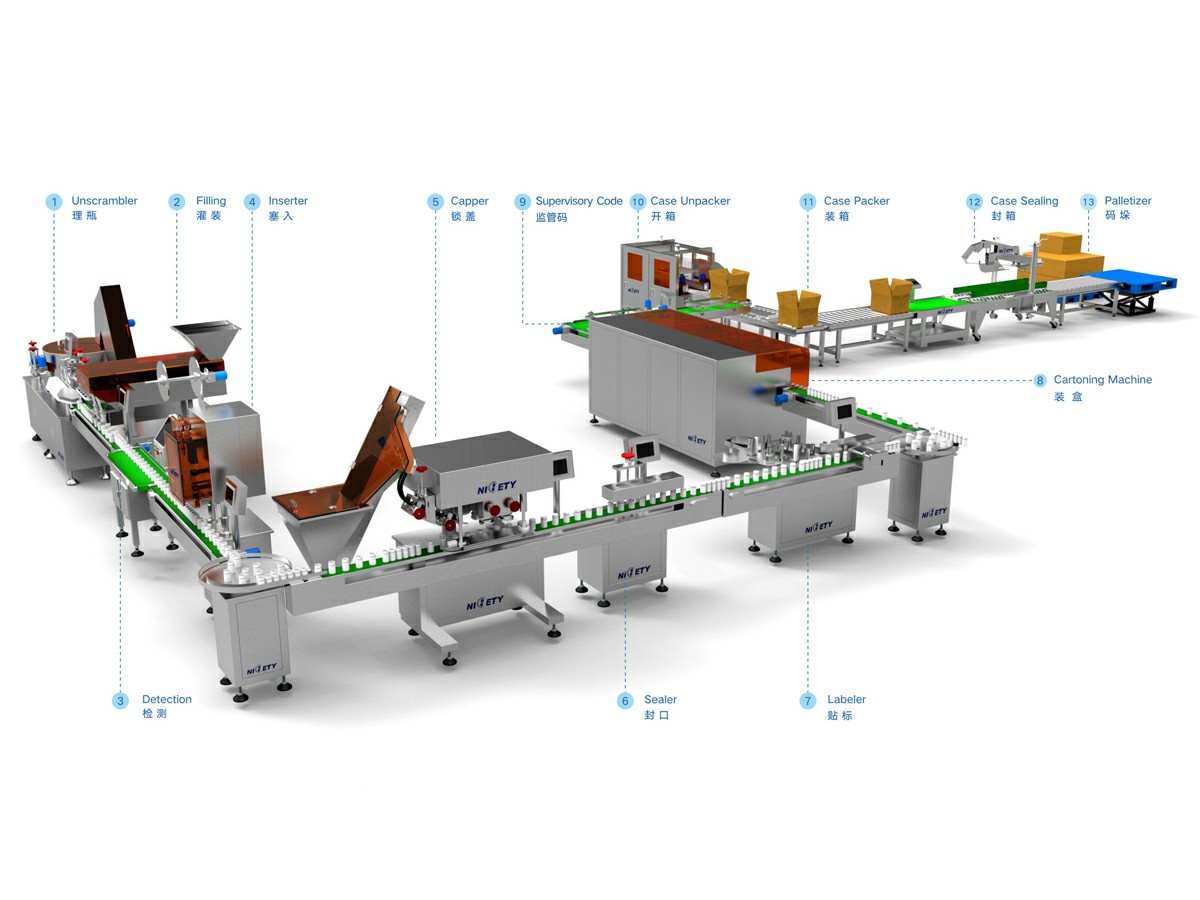

After stepping into the food industry, Hengli Packaging introduced the core technology advantage – electronic counting technology into food packaging, and used intelligent production to replace manual work to adapt to the rapidly changing food market and meet the needs of more diverse users. As a snack rising in recent years, cheese sticks have reached a market scale of 10 billion, and more and more businesses have started to join the track to increase the size of this category. However, in the process of conventional food production and packaging, intelligent production operations have not been fully popularized. It is not only time-consuming and labor-intensive to count and bag manually, but also difficult to be guaranteed in terms of safety and health

Based on the current situation of the industry, Hengli Packaging has actively developed intelligent multi granule technology suitable for food packaging to help users improve product competitiveness. Through the sustainable dialogue with consumers, we can effectively reach the product information and successfully unlock the next air outlet.

- Breaking through the difficulties in scanning and counting irregular shaped materials

Most of the cheese sticks on the market are irregular in shape, which is easy to cause errors in packaging due to counting errors in the process of using photoelectric eyes to scan. In view of these technical difficulties in application, Hengli Packaging actively discussed customization plans, unified the material handling track specifications according to the product shape and material quality, and ensured smooth operation of all links such as material handling, feeding, and feeding.

- The equipment is made of special materials and has big and wide-range compatibilities

The equipment involved in intelligent packaging production adopts sustainable and innovative materials, and has outstanding advantages such as low energy consumption and compact floor area during operation. In addition, the advanced photoelectric counting and metering technology overcomes the inaccuracy and slow speed of traditional weighing method for measuring and filling. It has great flexibility and adaptability, and can realize accurate measurement of products, rapid bagging, boxing, canning and other packaging forms, It is sufficient to meet any specific market demand.

- Simple and intelligent operation to help improve productivity

It is worth noting that the equipment in this application is equipped with an intelligent production management system, which can conduct self diagnosis and monitoring and effectively reduce the failure rate. The human-computer interactive operation mode, convenient command issuing and parameter one key storage, can realize fast and convenient intelligent production. In order to meet the needs of high-speed packaging production in the industry background, linear vibrators are used to feed materials stably and evenly, so as to achieve higher transportation speed and obtain greater production capacity.

- Effective identification and accurate counting of cheese sticks with special shapes

- Combine customer needs with its own technical advantages to stand the test of the future

- Intelligent production management system, helping to reduce dependence on personnel and improve production capacity and product competitiveness

Hengli Packaging should deal with the intelligent packaging production of cheese sticks and other products with special shape and appearance, which has typical reference significance for the entire packaging industry. At present, the method of manual counting packaging is out of date and has obvious disadvantages. Using machines to achieve automated packaging production can effectively save labor costs, while the core counting advantage of Hengli Packaging makes the entire packaging process very easy.

RECOMMENDED CASES

RELATED PRODUCTS

PARTNERS

for the current popular snack cheese bar “Hengli Packaging Realizes Intelligent Mixed Counting Packaging”

Intelligent multi grain bagging technology to meet the demand of food market

Project background

- After stepping into the food industry, Hengli Packaging introduced the core technology advantage – electronic counting technology into food packaging, and used intelligent production to replace manual work to adapt to the rapidly changing food market and meet the needs of more diverse users. As a snack rising in recent years, cheese sticks have reached a market scale of 10 billion, and more and more businesses have started to join the track to increase the size of this category. However, in the process of conventional food production and packaging, intelligent production operations have not been fully popularized. It is not only time-consuming and labor-intensive to count and bag manually, but also difficult to be guaranteed in terms of safety and health

- Based on the current situation of the industry, Hengli Packaging has actively developed intelligent multi granule technology suitable for food packaging to help users improve product competitiveness. Through the sustainable dialogue with consumers, we can effectively reach the product information and successfully unlock the next air outlet.

Practical application

- Breaking through the difficulties in scanning and counting irregular shaped materials

Most of the cheese sticks on the market are irregular in shape, which is easy to cause errors in packaging due to counting errors in the process of using photoelectric eyes to scan. In view of these technical difficulties in application, Hengli Packaging actively discussed customization plans, unified the material handling track specifications according to the product shape and material quality, and ensured smooth operation of all links such as material handling, feeding, and feeding.

- The equipment is made of special materials and has big and wide-range compatibilities

The equipment involved in intelligent packaging production adopts sustainable and innovative materials, and has outstanding advantages such as low energy consumption and compact floor area during operation. In addition, the advanced photoelectric counting and metering technology overcomes the inaccuracy and slow speed of traditional weighing method for measuring and filling. It has great flexibility and adaptability, and can realize accurate measurement of products, rapid bagging, boxing, canning and other packaging forms, It is sufficient to meet any specific market demand.

- Simple and intelligent operation to help improve productivity

It is worth noting that the equipment in this application is equipped with an intelligent production management system, which can conduct self diagnosis and monitoring and effectively reduce the failure rate. The human-computer interactive operation mode, convenient command issuing and parameter one key storage, can realize fast and convenient intelligent production. In order to meet the needs of high-speed packaging production in the industry background, linear vibrators are used to feed materials stably and evenly, so as to achieve higher transportation speed and obtain greater production capacity.

At a glance

- Effective identification and accurate counting of cheese sticks with special shapes

- Combine customer needs with its own technical advantages to stand the test of the future

- Intelligent production management system, helping to reduce dependence on personnel and improve production capacity and product competitiveness

Realistic meaning

Hengli Packaging should deal with the intelligent packaging production of cheese sticks and other products with special shape and appearance, which has typical reference significance for the entire packaging industry. At present, the method of manual counting packaging is out of date and has obvious disadvantages. Using machines to achieve automated packaging production can effectively save labor costs, while the core counting advantage of Hengli Packaging makes the entire packaging process very easy.