FROZEN FOOD

01

The packaging form of frozen food

Frozen food and frozen food are very different. Frozen food is more ready-to-eat, with simple operation and convenient satiety as the biggest selling point. The consumer group is mainly young people. For frozen food, it takes large quantity and convenient storage as the product advantage, and unified bagging of processed meat and cold chain transportation. The middle-end consumer group of this kind of food is mostly the kitchen of restaurants and canteens. With the popularity of central kitchen model, frozen food sales have been further broadened.

Hengli Packaging has recently received the demand for automatic counting and packaging of frozen chicken legs and wings. During the material testing process, it can be seen that Hengli Packaging is very handy for the packaging of such frozen products. Whatever packaging form is proposed by customers, it can be satisfied.

02

Counting device detail

- For frozen food, raw poultry, aquatic products and fruits and vegetables with less water are generally selected for freezing treatment and then packaged for transportation and sales. Therefore, the environment for packaging is very demanding, and temperature control is very important. Hengli Packaging has a successful experience in automating COVID-19 vaccine packaging at low temperatures, and it is also worth learning from when applying it to frozen food.

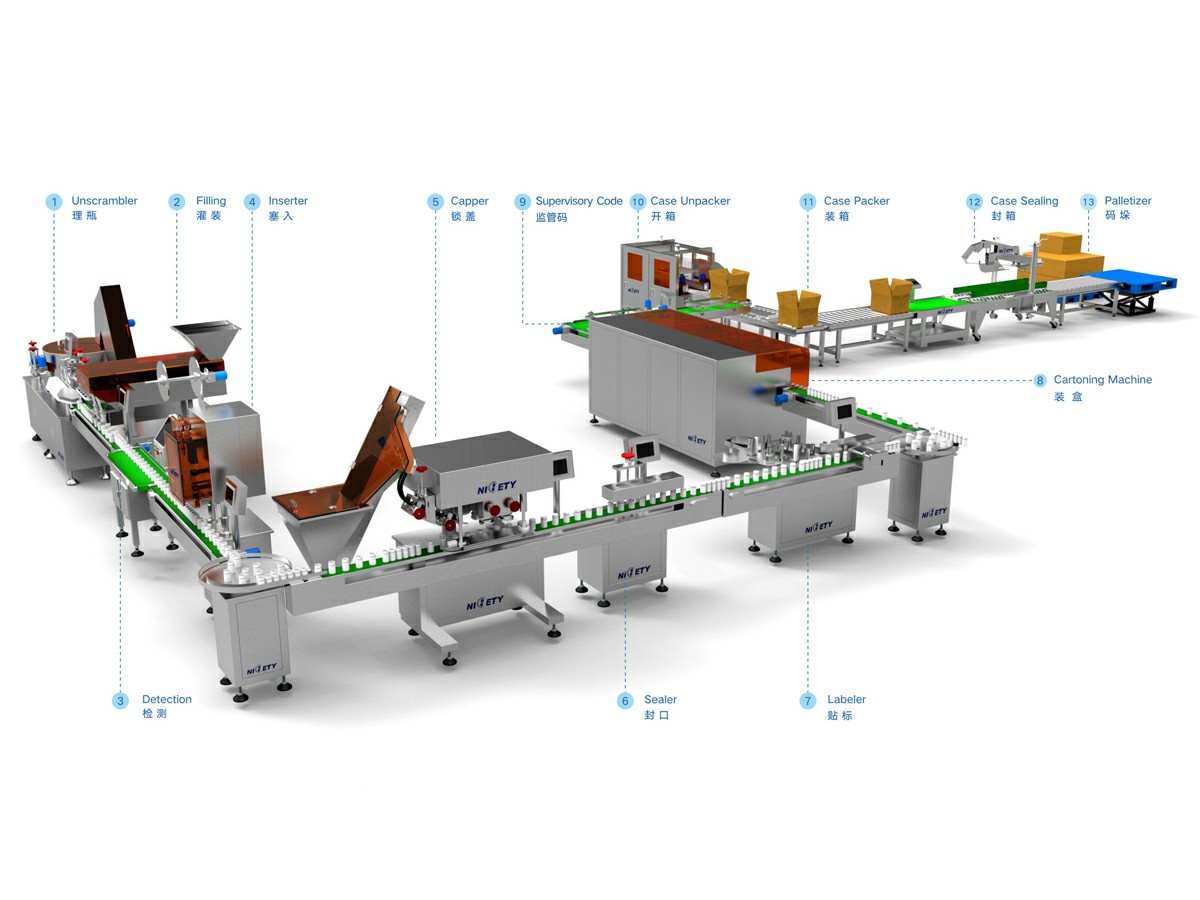

- After solving the possible influence of temperature on packaging, we use intelligent system to control automatic counting equipment for packaging production, which is the technical advantage accumulated by Hengli packaging for a long time. With the front and back of the equipment flexible composition of a complete production line, relying on intelligent system control and management of the whole process, simple and efficient, effectively improve the level of packaging.

03

Highlights of equipment packaging

- Equipment to maintain high flexibility and high performance

- In line with food hygiene industry standards of equipment and materials, safe and assured

- Provides an efficient and consistent process with high quality

FROZEN FOOD

01

The packaging form of frozen food

Frozen food and frozen food are very different. Frozen food is more ready-to-eat, with simple operation and convenient satiety as the biggest selling point. The consumer group is mainly young people. For frozen food, it takes large quantity and convenient storage as the product advantage, and unified bagging of processed meat and cold chain transportation. The middle-end consumer group of this kind of food is mostly the kitchen of restaurants and canteens. With the popularity of central kitchen model, frozen food sales have been further broadened.

Hengli Packaging has recently received the demand for automatic counting and packaging of frozen chicken legs and wings. During the material testing process, it can be seen that Hengli Packaging is very handy for the packaging of such frozen products. Whatever packaging form is proposed by customers, it can be satisfied.

02

Counting device detail

- For frozen food, raw poultry, aquatic products and fruits and vegetables with less water are generally selected for freezing treatment and then packaged for transportation and sales. Therefore, the environment for packaging is very demanding, and temperature control is very important. Hengli Packaging has a successful experience in automating COVID-19 vaccine packaging at low temperatures, and it is also worth learning from when applying it to frozen food.

- After solving the possible influence of temperature on packaging, we use intelligent system to control automatic counting equipment for packaging production, which is the technical advantage accumulated by Hengli packaging for a long time. With the front and back of the equipment flexible composition of a complete production line, relying on intelligent system control and management of the whole process, simple and efficient, effectively improve the level of packaging.

03

Highlights of equipment packaging

- Equipment to maintain high flexibility and high performance

- In line with food hygiene industry standards of equipment and materials, safe and assured

- Provides an efficient and consistent process with high quality