TABLET CANDY

01

The packaging form of laminated candy

Tablet candy is not rare in the consumer market. In addition to the classification of snacks, health products, calcium tablets, vitamin C lozenges and other products will also be produced through the solid form of tablet. The advantage of this product form is that it does not occupy a large space and is easy to store and transport, so the pressure candy mostly uses the packaging form of canning, bottling and bagging. And because the shape of this kind of candy is relatively conventional, automatic packaging can be easily realized for the counting equipment of constant force packaging.

However, with the change of consumer demand, mixed packaging is more in line with the mentality of consumers who want to try different tastes. Manufacturers of laminated candy also begin to seek more packaging possibilities related to mixed packaging. For Hengli Packaging, mixed packaging has always been the core technology advantage, no matter what form of packaging customers want to carry out the application, there is no problem.

02

Counting device detail

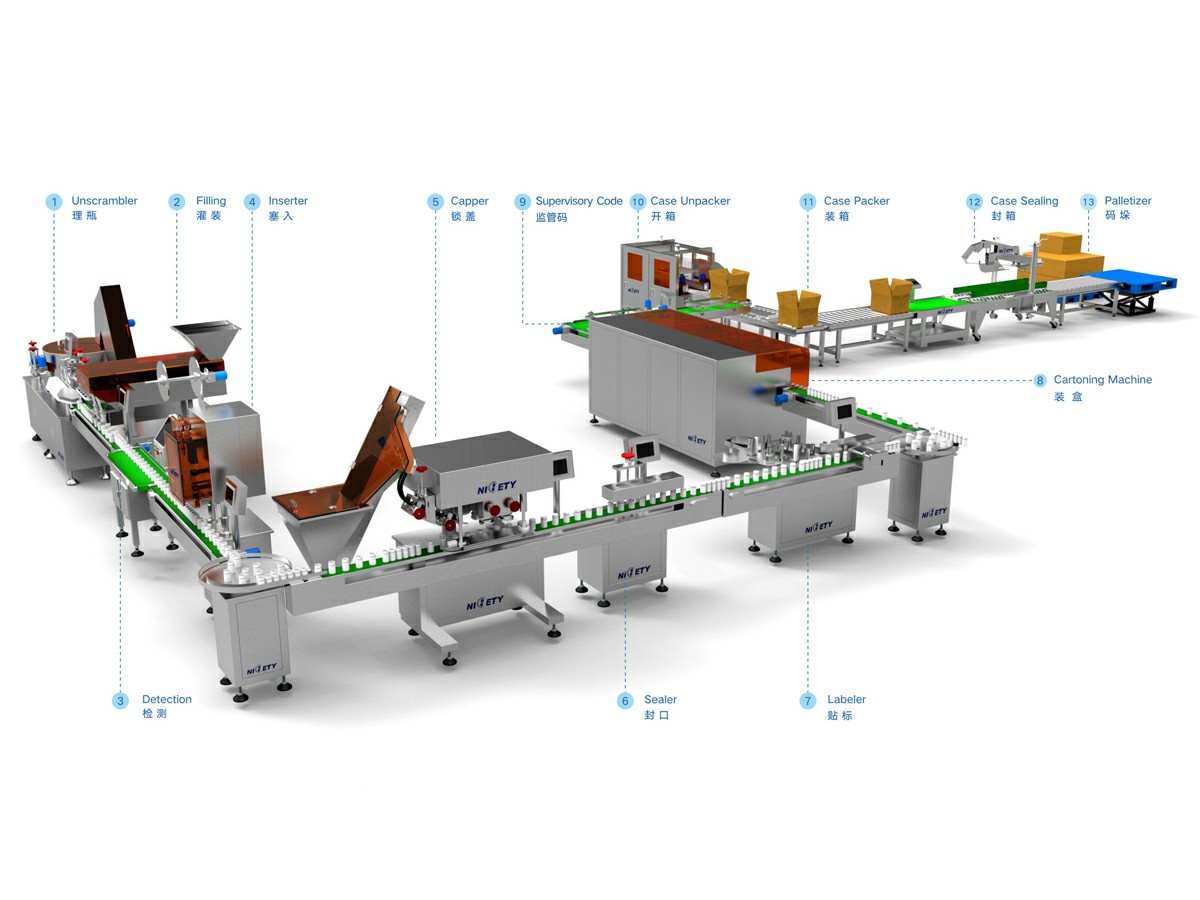

The automatic counting process of tablet candy is similar to the packaging process of tablets and other drugs. The materials are separated by vibration track (vibration frequency can be adjusted according to different states of materials), photoelectric eye can recognize different shapes of tablet candy, and intelligent display screen can adjust relevant parameters and set the number of filling grains. Independent pillow bag of oral lozenges bagging, canning can also be unified weighing or accurate counting, to achieve batch packaging. The whole packaging process is less controlled, and the whole production process is highly efficient, safe and cost-effective.

03

Highlights of equipment packaging

- Interactive design, intelligent display direct operation control, convenient and quick, save labor

- In line with the food processing industry health standards of equipment and materials, packaging environment safety degree

- Gentle product handling, and strive to reduce the damage to the product materials

TABLET CANDY

01

The packaging form of laminated candy

Tablet candy is not rare in the consumer market. In addition to the classification of snacks, health products, calcium tablets, vitamin C lozenges and other products will also be produced through the solid form of tablet. The advantage of this product form is that it does not occupy a large space and is easy to store and transport, so the pressure candy mostly uses the packaging form of canning, bottling and bagging. And because the shape of this kind of candy is relatively conventional, automatic packaging can be easily realized for the counting equipment of constant force packaging.

However, with the change of consumer demand, mixed packaging is more in line with the mentality of consumers who want to try different tastes. Manufacturers of laminated candy also begin to seek more packaging possibilities related to mixed packaging. For Hengli Packaging, mixed packaging has always been the core technology advantage, no matter what form of packaging customers want to carry out the application, there is no problem.

02

Counting device detail

The automatic counting process of tablet candy is similar to the packaging process of tablets and other drugs. The materials are separated by vibration track (vibration frequency can be adjusted according to different states of materials), photoelectric eye can recognize different shapes of tablet candy, and intelligent display screen can adjust relevant parameters and set the number of filling grains. Independent pillow bag of oral lozenges bagging, canning can also be unified weighing or accurate counting, to achieve batch packaging. The whole packaging process is less controlled, and the whole production process is highly efficient, safe and cost-effective.

03

Highlights of equipment packaging

- Interactive design, intelligent display direct operation control, convenient and quick, save labor

- In line with the food processing industry health standards of equipment and materials, packaging environment safety degree

- Gentle product handling, and strive to reduce the damage to the product materials