FRUIT HARD CANDY

01

The packaged form of fruit hard candy

In today’s candy market, fruit candy has been deeply loved by consumers because of its colorful color and diversified taste. In the packaging, fruit candy also presents a different appearance from other products, such as bagging, canning, box packing… Everything, even the packaging material needs to be selected according to the material and selling point of the candy. In addition to the eye-catching appearance of packaging, manufacturers also hope to meet the taste of most consumers in the form of packaging, so mixed packaging is also a very important link in the form of hard candy packaging.

Mixed packaging and automatic counting are the core technical advantages of Hengli Packaging, which can be applied to the packaging of fruit hard candy, helping related enterprises to improve the packaging level and market competitiveness, so as to move towards a new world of intelligent packaging.

02

Counting device detail

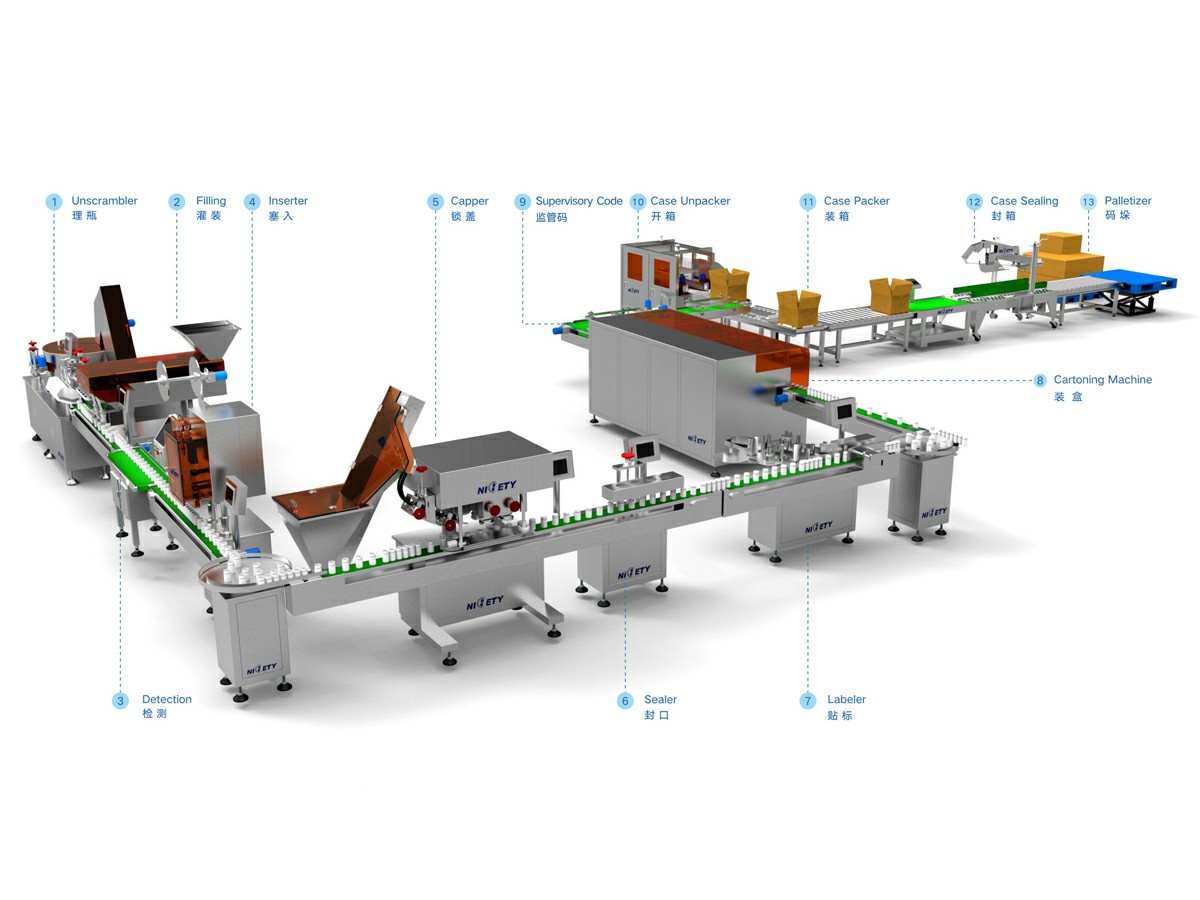

Connected with the front-end feeding equipment, the fruit candy is transported to the vibration track, and dynamic interaction is realized through the electronic screen. The packaging process is monitored in real time, and relevant parameters are adjusted to ensure that the material will not be unnecessarily damaged due to too large vibration amplitude. In addition, for different packaging requirements of customers, whether it is canning, bagging or box packing, similar product packaging or mixed packaging, Hengli packaging automation equipment can form a complete packaging line with related equipment. The very compact circuit concept and high availability make the automation equipment produced by Hengli Packaging can meet the packaging requirements of different types of fruit hard candy.

03

Highlights of equipment packaging

- Adjust parameters through the electronic screen, intelligent management system, convenient and fast

- Reliable quality control and gentle handling of products

- Flexible coordination of the whole packaging process brings excellent performance

FRUIT HARD CANDY

01

The packaged form of fruit hard candy

In today’s candy market, fruit candy has been deeply loved by consumers because of its colorful color and diversified taste. In the packaging, fruit candy also presents a different appearance from other products, such as bagging, canning, box packing… Everything, even the packaging material needs to be selected according to the material and selling point of the candy. In addition to the eye-catching appearance of packaging, manufacturers also hope to meet the taste of most consumers in the form of packaging, so mixed packaging is also a very important link in the form of hard candy packaging.

Mixed packaging and automatic counting are the core technical advantages of Hengli Packaging, which can be applied to the packaging of fruit hard candy, helping related enterprises to improve the packaging level and market competitiveness, so as to move towards a new world of intelligent packaging.

02

Counting device detail

Connected with the front-end feeding equipment, the fruit candy is transported to the vibration track, and dynamic interaction is realized through the electronic screen. The packaging process is monitored in real time, and relevant parameters are adjusted to ensure that the material will not be unnecessarily damaged due to too large vibration amplitude. In addition, for different packaging requirements of customers, whether it is canning, bagging or box packing, similar product packaging or mixed packaging, Hengli packaging automation equipment can form a complete packaging line with related equipment. The very compact circuit concept and high availability make the automation equipment produced by Hengli Packaging can meet the packaging requirements of different types of fruit hard candy.

03

Highlights of equipment packaging

- Adjust parameters through the electronic screen, intelligent management system, convenient and fast

- Reliable quality control and gentle handling of products

- Flexible coordination of the whole packaging process brings excellent performance