CHOCDAY

01

CHOCDAY package form

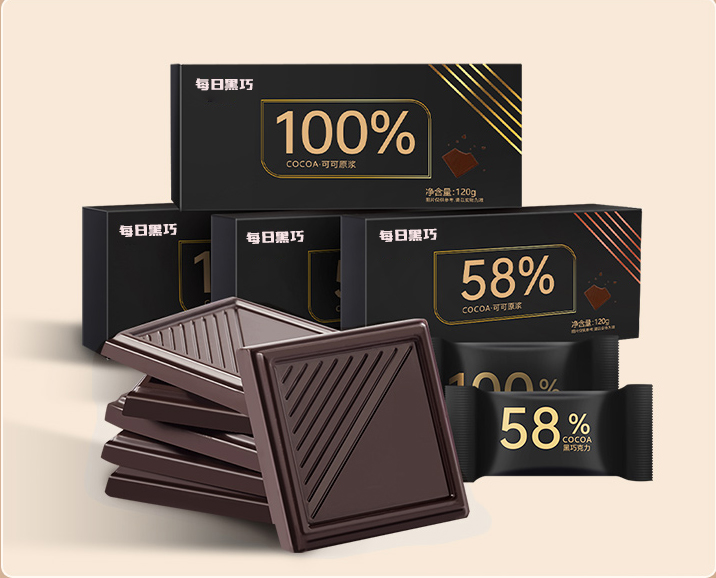

As a chocolate brand rising recently, CHOCDAY creates a new concept of “functional chocolate” through key words marketing such as pure cocoa butter and zero sugar, and successfully occupies the consumption market of generation Z, leaving a unique place for a domestic brand in this chocolate market which is now monopolized by foreign giants. The popularity of daily black Qiao this category also let the major brands began to imitate, the first bright packaging form is a big eye suction tool: independent pillow packaging box, open ready-to-eat at the same time is easy to carry and share. Combined with the current popularity of mixed packaging, a box mixed with a variety of flavors, to meet consumers better than taste mentality.

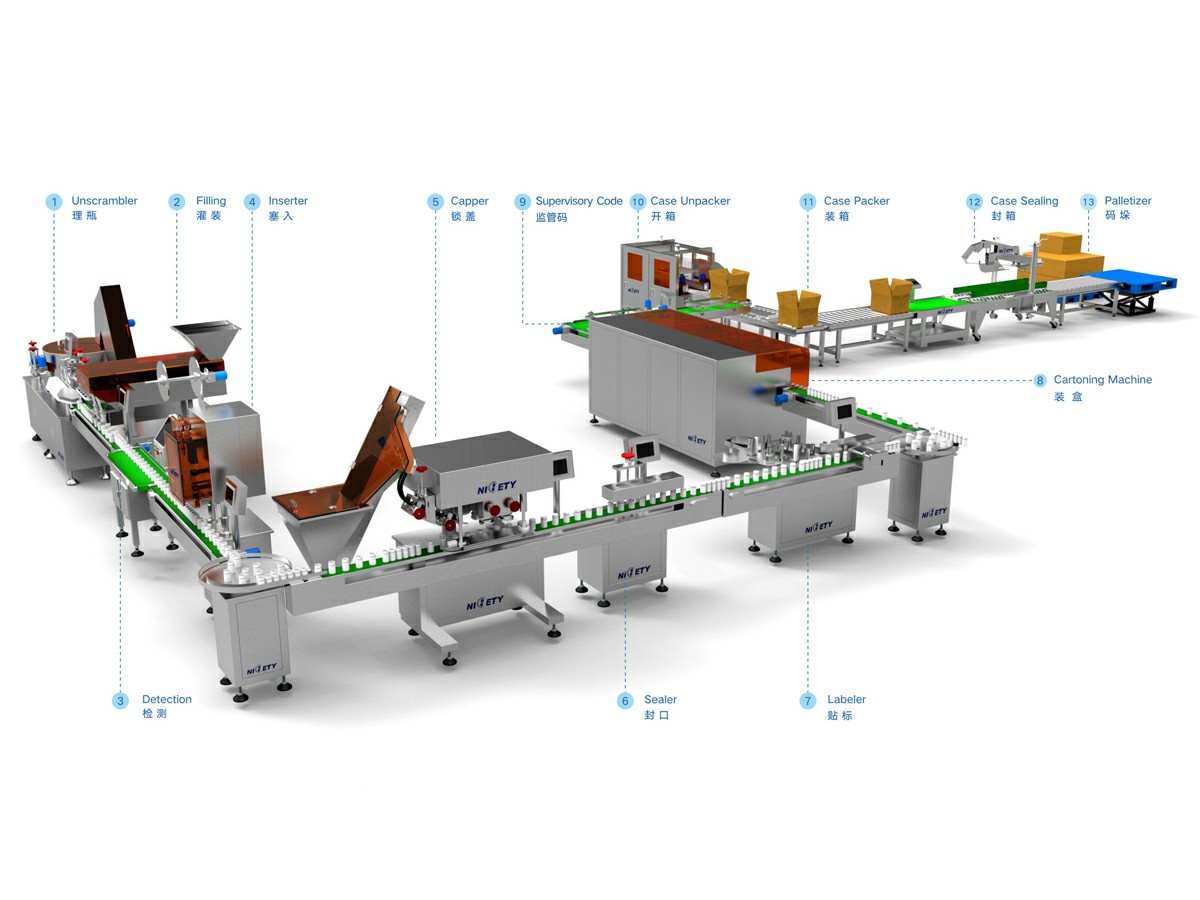

Hengli Packaging has been deeply engaged in the automated packaging and counting industry for many years, so it can be said that it is quite handy for similar packaging needs of CHOCDAY. No matter it is packed in boxes, cans or bags, it is flexibly connected with the back-end packaging to realize any form of packaging needs.

02

Counting device detail

In the CHOCDAY automatic packaging process of independent pillow bags, the shape can be accurately identified by the photoelectric eye of constant force packaging, and the vibration amplitude of the vibration track can be adjusted by the button through interaction with the electronic screen, so that the process of feeding, collecting and counting can be flexible and smooth. Modular machine design, cost-effective solutions and reliable processing of special materials are the professional qualities Hengli Packaging demonstrates in the automated packaging process. Complete packaging production line with front and back equipment, based on extensive experience and the use of the latest technology development, to provide user-oriented operating experience.

03

Highlights of equipment packaging

- Modular machine concept brings a high degree of flexibility to the packaging process

- High form varieties, including conversion between single and mixed varieties

- Through innovative forms, to achieve mild product handling

CHOCDAY

01

CHOCDAY package form

As a chocolate brand rising recently, CHOCDAY creates a new concept of “functional chocolate” through key words marketing such as pure cocoa butter and zero sugar, and successfully occupies the consumption market of generation Z, leaving a unique place for a domestic brand in this chocolate market which is now monopolized by foreign giants. The popularity of daily black Qiao this category also let the major brands began to imitate, the first bright packaging form is a big eye suction tool: independent pillow packaging box, open ready-to-eat at the same time is easy to carry and share. Combined with the current popularity of mixed packaging, a box mixed with a variety of flavors, to meet consumers better than taste mentality.

Hengli Packaging has been deeply engaged in the automated packaging and counting industry for many years, so it can be said that it is quite handy for similar packaging needs of CHOCDAY. No matter it is packed in boxes, cans or bags, it is flexibly connected with the back-end packaging to realize any form of packaging needs.

02

Counting device detail

In the CHOCDAY automatic packaging process of independent pillow bags, the shape can be accurately identified by the photoelectric eye of constant force packaging, and the vibration amplitude of the vibration track can be adjusted by the button through interaction with the electronic screen, so that the process of feeding, collecting and counting can be flexible and smooth. Modular machine design, cost-effective solutions and reliable processing of special materials are the professional qualities Hengli Packaging demonstrates in the automated packaging process. Complete packaging production line with front and back equipment, based on extensive experience and the use of the latest technology development, to provide user-oriented operating experience.

03

Highlights of equipment packaging

- Modular machine concept brings a high degree of flexibility to the packaging process

- High form varieties, including conversion between single and mixed varieties

- Through innovative forms, to achieve mild product handling