PACKAGING ENGINEERING

“Stable coordination system, unified planning and implementation”

Hengli packaging can provide the whole line of integrated packaging engineering, easy to deal with a variety of packaging problems. For customers with such needs, it is no longer necessary to worry about the problem that all parts of the equipment are not matched and cannot be smoothly put into packaging production. After continuous and stable offline output, the whole line project produced by Hengli has proved its stable and efficient equipment performance and flexible and attractive market value. As for the necessary links of primary packaging, process packaging and end packaging, they are determined and implemented after unified planning to ensure the stability in the actual operation process. The whole line packaging project produced by Hengli helps customers save the time of their own equipment, clean up the possible problems of installation and debugging in advance, and imprint the stability and efficiency on their hearts.

- ADVANTAGE IN PRACTICE

» CONVENIENT AND LABOR-SAVING

The whole set of packaging production line, save you inquire about the price and equipment of the time, each part of the complete links, tacit cooperation, do not have to worry about the production problems because of the mismatch.

» STABILITY AND EFFICIENCY COEXISTSTABILITY AND EFFICIENCY COEXIST

The natural tacit understanding makes the equipment produced by Hengli packaging have advantages in price and quality at the same time. After the skillful assembly of the technical department, it makes long-term high-speed production possible.

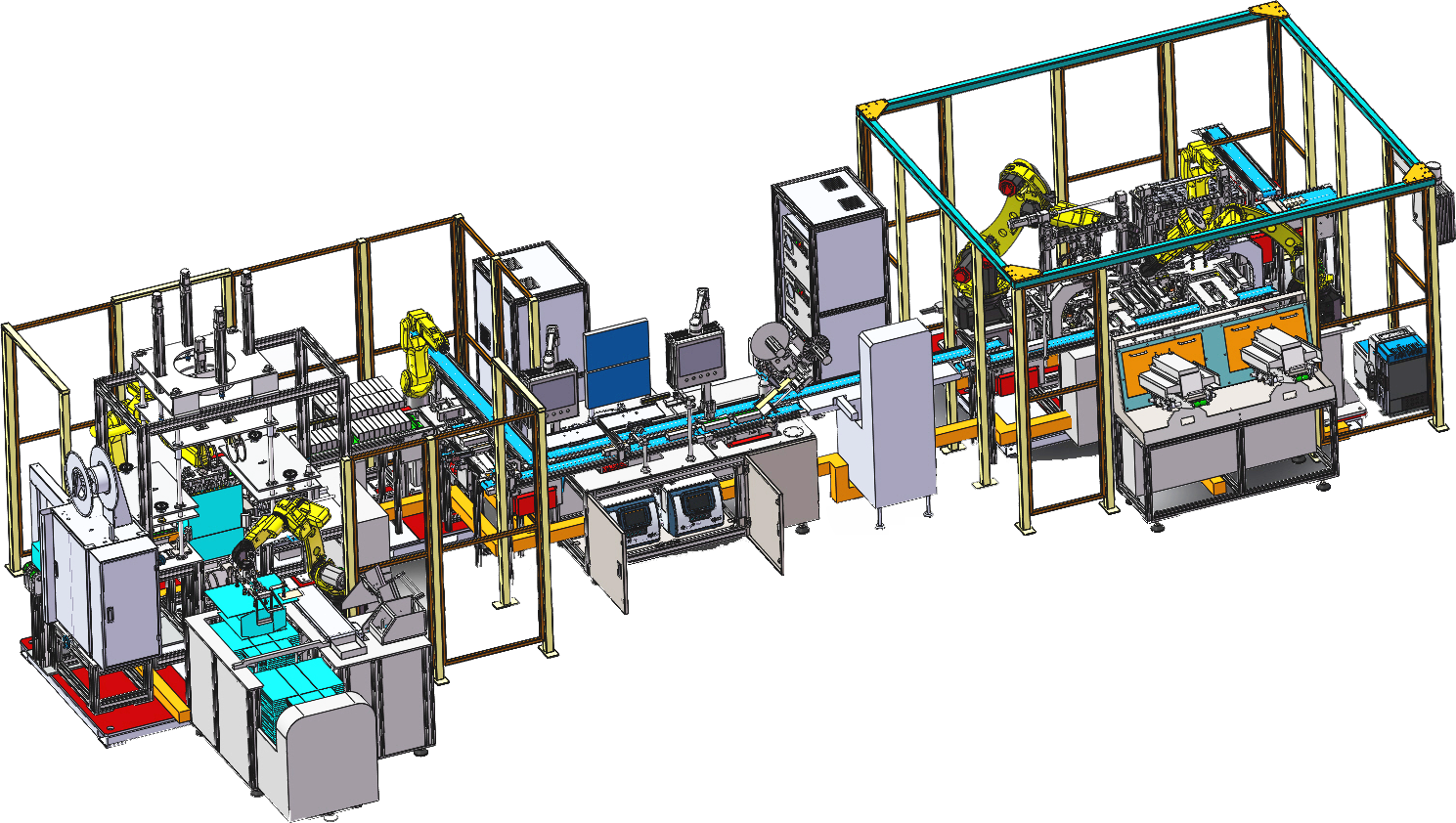

» FULLY AUTOMATIC INTELLIGENCE TO ACHIEVE INTEGRATION

Hengli packaging has taken the express train of the age of science and technology, the use of efficient intelligent operation to solve a series of production and packaging problems from the root of the enterprise, for the whole line of packaging engineering, the realization of intelligent integration is conducive to quickly find out the crux of the fault.

- SCOPE OF APPLICATION

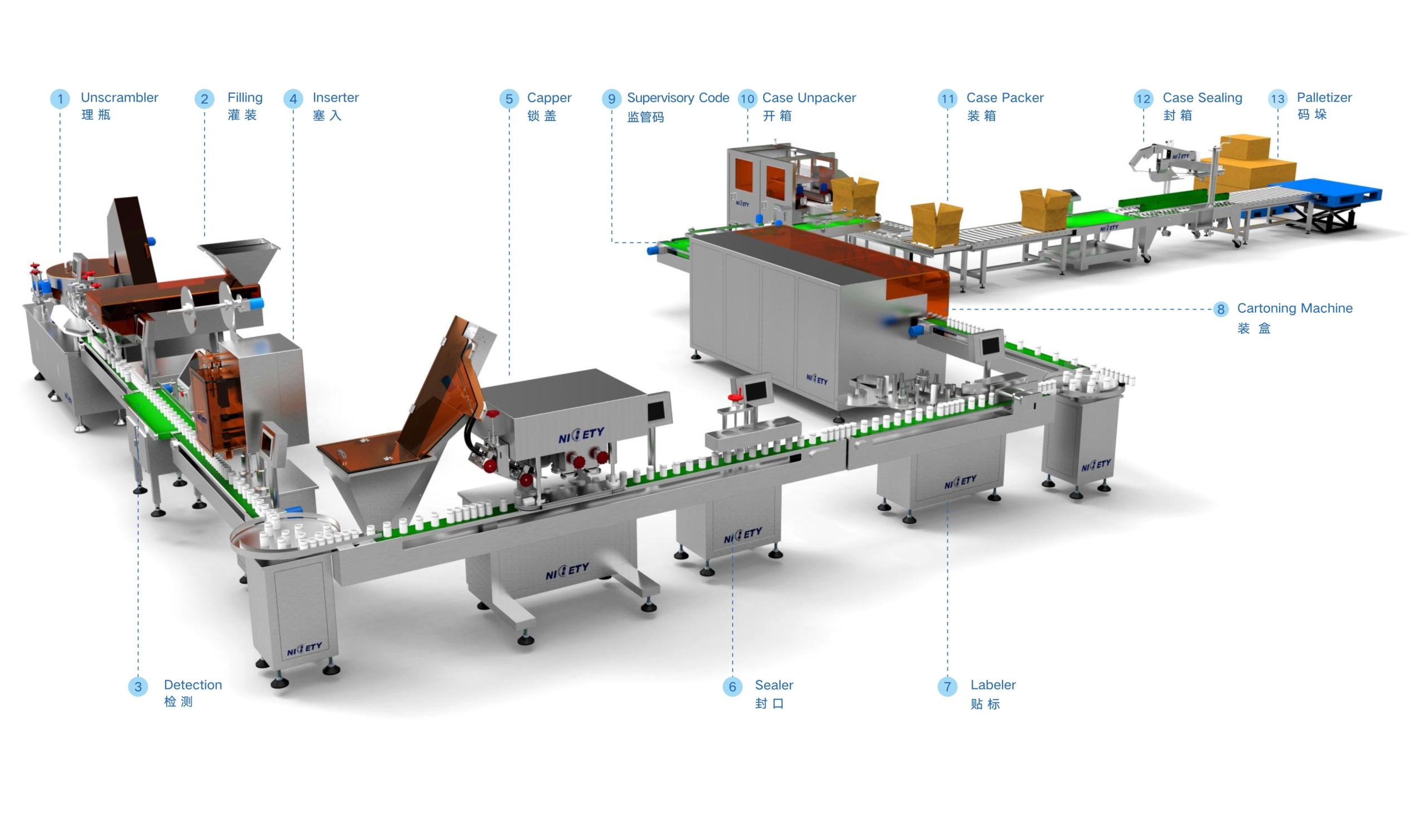

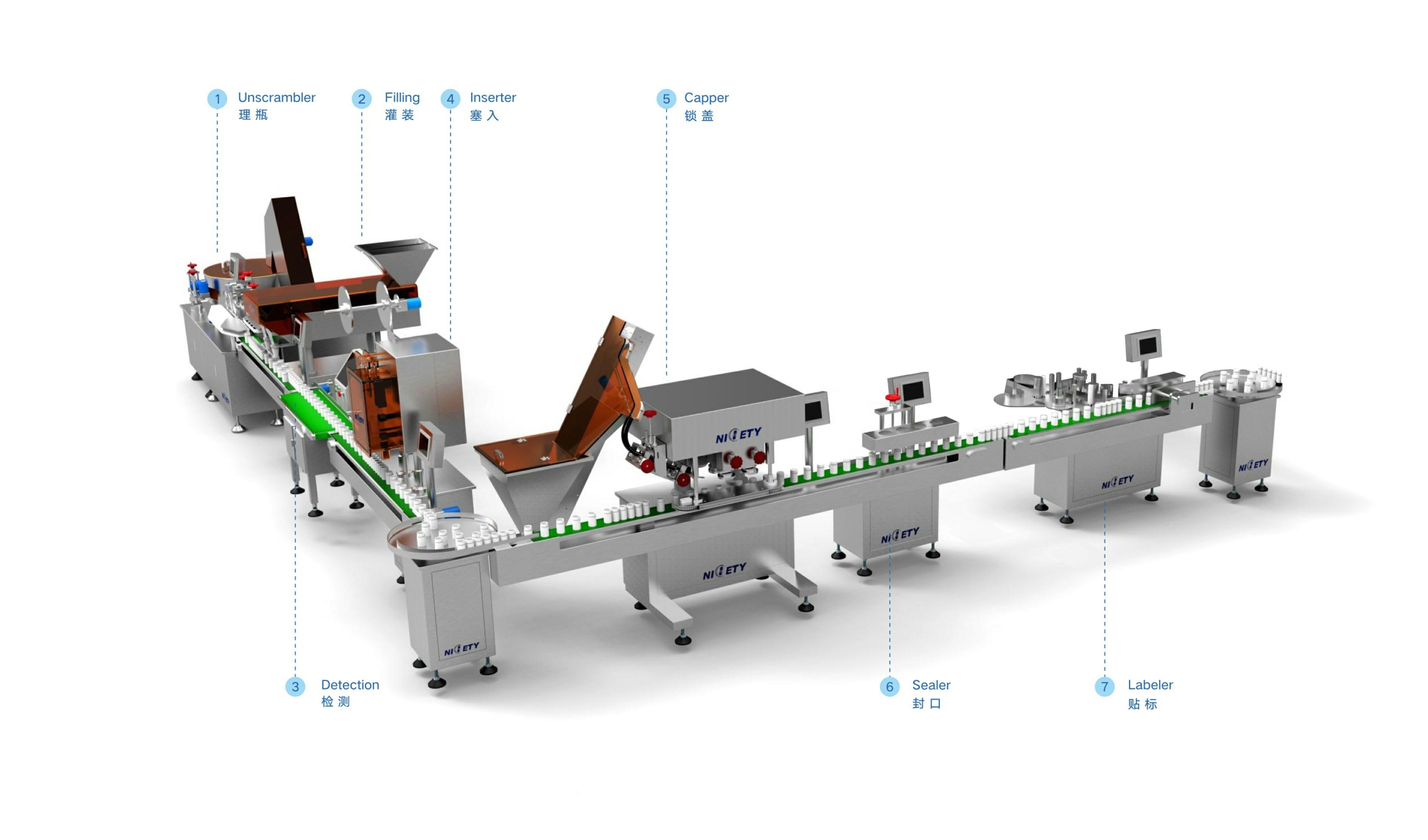

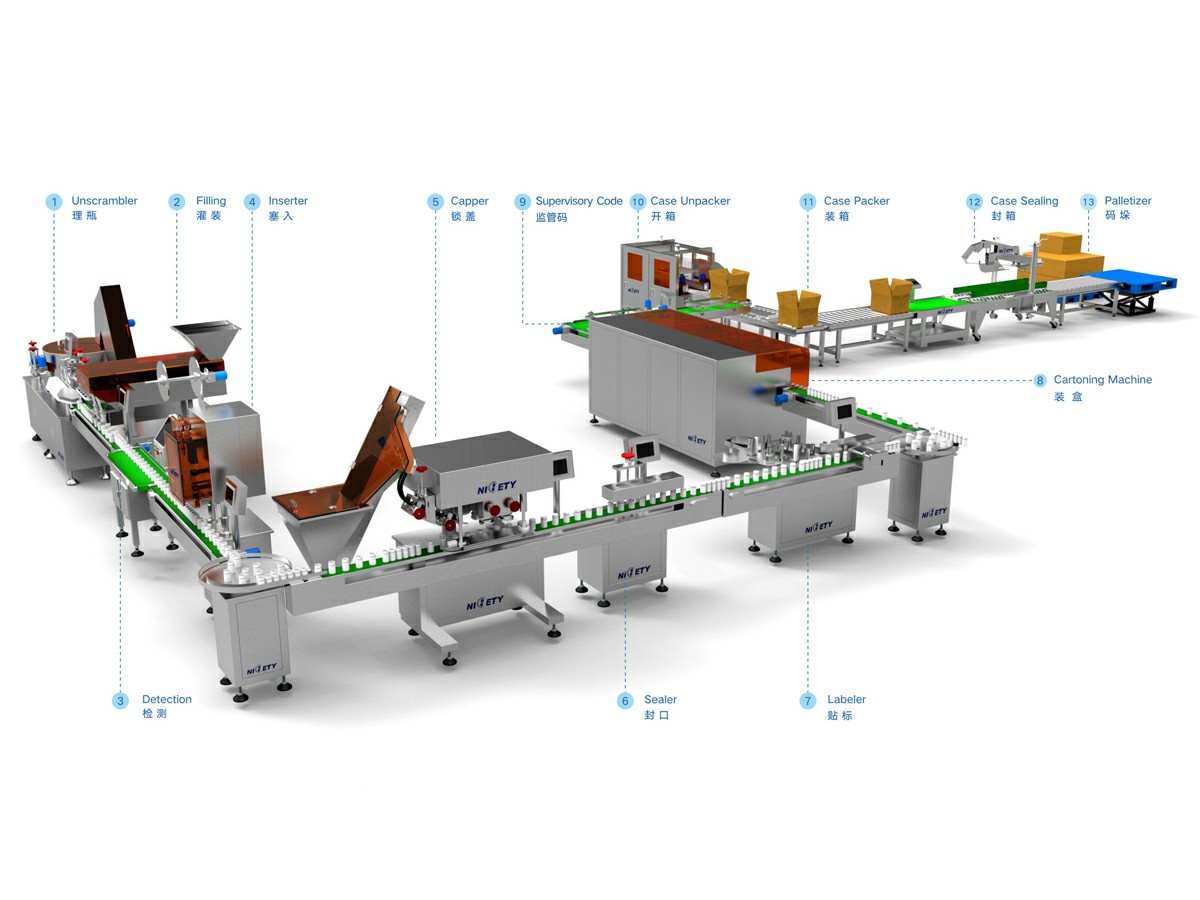

» SUITABLE FOR THE FULL PACKAGE PROCESS OF DRUGS

It includes a series of linkage packaging production lines from Bottle management → Filling → Testing → Stuffing → Locking → Sealing → Labeling → Packing → Supervision code → Unpacking → Packing → Sealing → Palletizing, with intelligent overall packaging technology solutions, real-time monitoring and strict quality control.

» AN IMPORTANT PART OF THE PACKAGING PROCESS

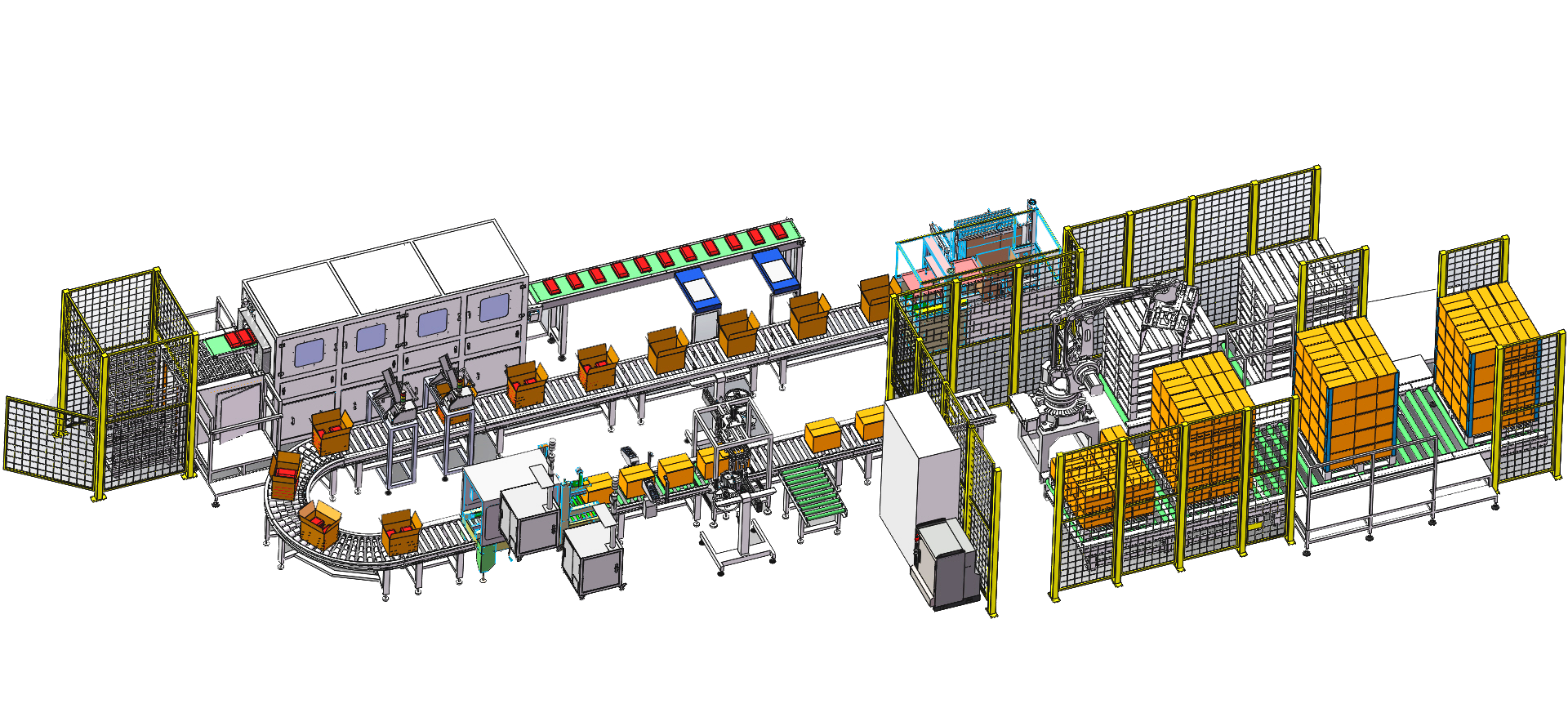

Various detailed data Settings involving transportation, feeding, bagging and other links, LED operation screen, background data storage, real-time update and sharing.

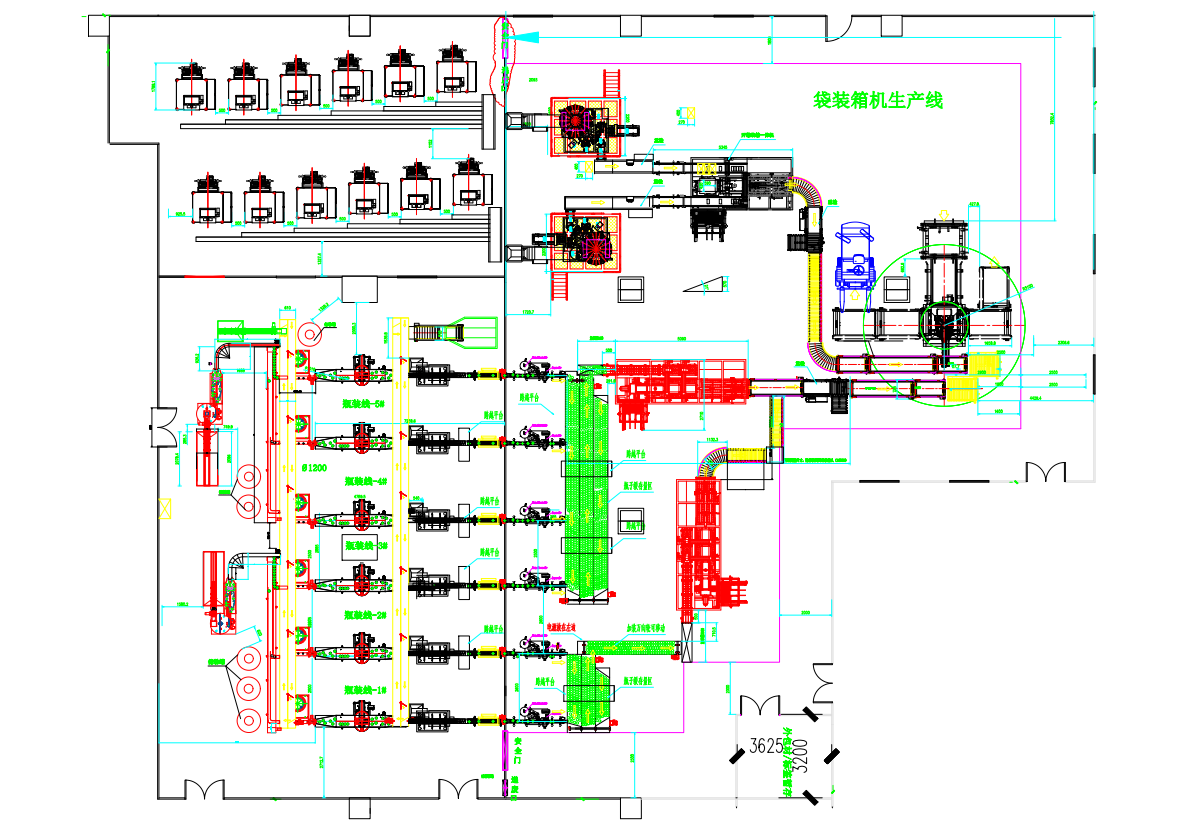

- ACTUAL CASE

PACKAGING ENGINEERING

“Stable coordination system, unified planning and implementation”

Hengli packaging can provide the whole line of integrated packaging engineering, easy to deal with a variety of packaging problems. For customers with such needs, it is no longer necessary to worry about the problem that all parts of the equipment are not matched and cannot be smoothly put into packaging production. After continuous and stable offline output, the whole line project produced by Hengli has proved its stable and efficient equipment performance and flexible and attractive market value. As for the necessary links of primary packaging, process packaging and end packaging, they are determined and implemented after unified planning to ensure the stability in the actual operation process. The whole line packaging project produced by Hengli helps customers save the time of their own equipment, clean up the possible problems of installation and debugging in advance, and imprint the stability and efficiency on their hearts.

- ADVANTAGE IN PRACTICE

» CONVENIENT AND LABOR-SAVING

The whole set of packaging production line, save you inquire about the price and equipment of the time, each part of the complete links, tacit cooperation, do not have to worry about the production problems because of the mismatch.

» STABILITY AND EFFICIENCY COEXISTSTABILITY AND EFFICIENCY COEXIST

The natural tacit understanding makes the equipment produced by Hengli packaging have advantages in price and quality at the same time. After the skillful assembly of the technical department, it makes long-term high-speed production possible.

» FULLY AUTOMATIC INTELLIGENCE TO ACHIEVE INTEGRATION

Hengli packaging has taken the express train of the age of science and technology, the use of efficient intelligent operation to solve a series of production and packaging problems from the root of the enterprise, for the whole line of packaging engineering, the realization of intelligent integration is conducive to quickly find out the crux of the fault.

- SCOPE OF APPLICATION

› SUITABLE FOR THE FULL PACKAGE PROCESS OF DRUGS

It includes a series of linkage packaging production lines from Bottle management → Filling → Testing → Stuffing → Locking → Sealing → Labeling → Packing → Supervision code → Unpacking → Packing → Sealing → Palletizing, with intelligent overall packaging technology solutions, real-time monitoring and strict quality control.

› AN IMPORTANT PART OF THE PACKAGING PROCESS

Various detailed data Settings involving transportation, feeding, bagging and other links, LED operation screen, background data storage, real-time update and sharing.

- ACTUAL CASE