Intelligent electronic several piece equipment packaging and care products – BEAD BAG

Fully automated packaging production line can greatly improve efficiency and save labor costs, making packaging easier and more convenient

01

Fully automated packaging production line can greatly improve efficiency and save labor costs, making packaging easier and more convenient

Laundry clotting beads were introduced into China by P&G in 2014, and then domestic brands successively increased their weight and launched multi cavity clotting beads integrating washing and nursing. The research shows that the main purchase channels of this kind of independently packaged concentrated washing and nursing products are concentrated online, and the main consumers are young people. According to the data, the post-90s are the main consumers of laundry beads, accounting for more than 50%, of which the 90-95 accounts for the highest proportion, accounting for 32%, and the post-95 accounts for 23%. On the whole, the laundry beads have the advantages of convenience and quickness, and they have a strong appeal to the young generation. In addition, the young generation has a strong ability to accept new things faster, so the laundry beads are mainly young people at present. It is expected that with the continuous penetration of laundry beads, it is expected to be popularized to all ages.

The Research Report on the Market Operation Situation and Investment Strategy of China’s Laundry Coagulation Industry from 2022 to 2027 released by Huajing Industry Research Institute pointed out that the year 2020, when the epidemic broke out, was a good opportunity for the development of laundry beads. The turnover of a brand on the e-commerce platform exceeded 100 million, with a year-on-year growth rate of more than 200%. For manufacturers, concentrated laundry beads are very profitable, even saving 7% of the packaging cost and 4.2% of the freight. It can be seen that there is still a large market penetration space for laundry beads. With the rising consumer awareness and acceptance, laundry beads are expected to become the main force in the future laundry market.

With the increasing expansion of the laundry bead market, the demand for its automated packaging has become increasingly strong. Hengli Packaging is fully capable of helping this type of product innovate its packaging form and improve its packaging level by relying on its own technical advantages when receiving inquiries from relevant customers.

02

Necessity of Automatic Packaging of Laundry Coagulation Beads with Intelligent Counting Equipment

- Market development potential not to be underestimated

Through the analysis of a series of development processes after the coagulating beads bag officially entered the Chinese market, it can be seen that its light, fast and powerful cleaning ability has been favored by more and more young consumers, and it also has a trend of gradually penetrating into the whole age group. In order to meet the order demand of higher output, more and more enterprises begin to choose automated packaging instead of manual production.

- The Mature Development of Automatic Packaging Technology

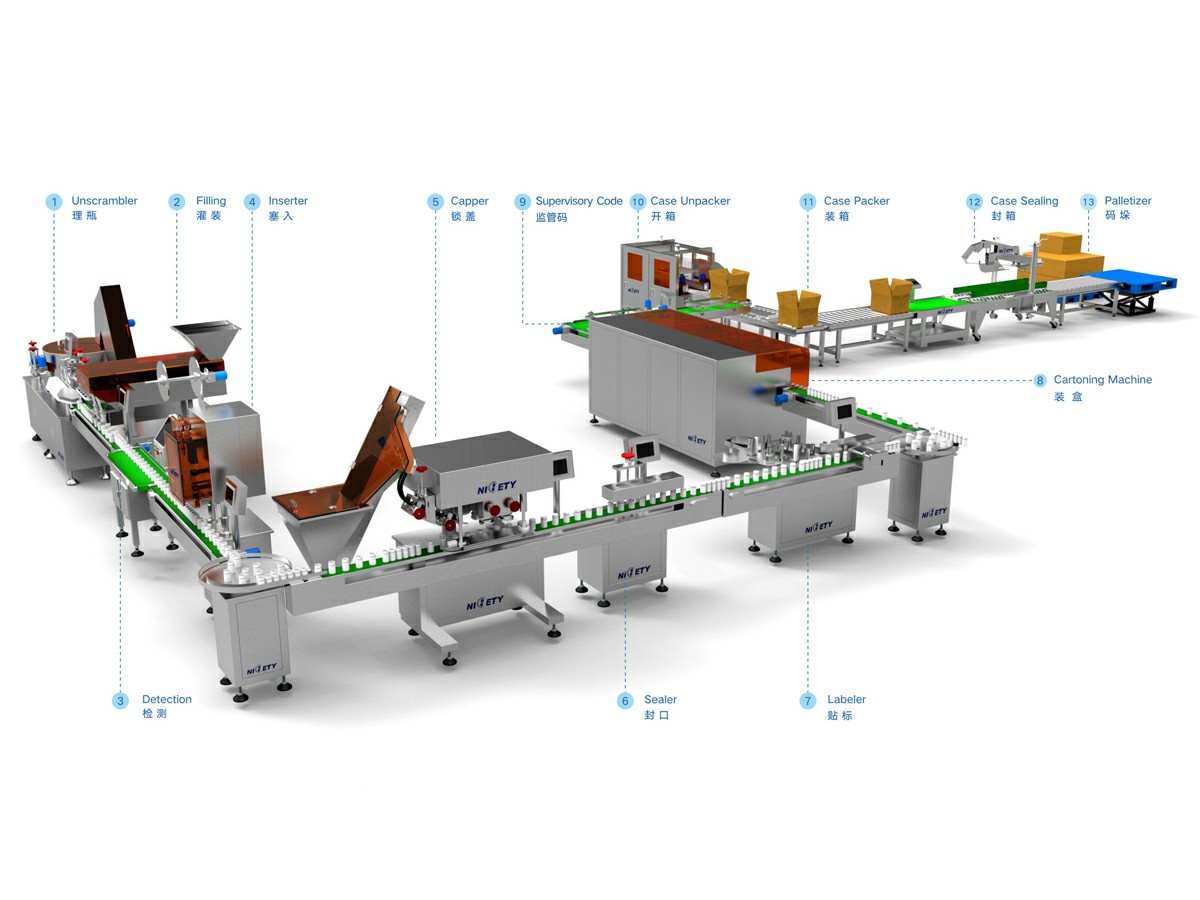

Relying on the rich experience accumulated by Hengli Packaging in the automatic packaging industry for more than ten years, the technology has become quite mature in the face of the automatic packaging demand for products such as bead packs. In the actual packaging process, the automatic counting equipment of Hengli Packaging can accurately identify and package products of any shape, material and size. Compared with manual picking, the fully automated packaging production line can greatly improve efficiency and save labor costs, making packaging easier and more convenient.

03

Difficulties in automatic packaging for beads

The coagulating bead bag is used to wrap the concentrated laundry detergent with a water-soluble polymer material, which is as tough as plastic at room temperature and convenient for transportation and storage. The shape and texture of the beading bag have been determined, but due to its special shape, it needs to be accurately identified with customized solutions. Hengli Packaging can effectively solve such problems through its own professional technology. In addition, some customers put forward the concept of mixed packaging, which can also realize the complete packaging process from initial material handling to end sealing and palletizing through multiple automatic particle counting equipment. No matter the different packaging forms of cartoning, bagging or canning, they can also be flexibly adjusted to achieve the goal in one step.

04

Advantages of introducing intelligent counting equipment for automatic packaging for bead packs

- Fully automatic production line, human-computer interaction page setting, parameter storage, simple and fast

- Intelligent production management system, fast speed and high efficiency, effectively improving productivity

- Multi level vibration track, which can adjust the vibration level at any time to ensure that the product will not be damaged

- Flexible to adapt to products of various sizes and shapes, and any packaging form can meet

Intelligent electronic several piece equipment packaging and care products – bead bag

Fully automated packaging production line can greatly improve efficiency and save labor costs, making packaging easier and more convenient

01

Analysis on the Market Quotations of Coagulation Beads

Laundry clotting beads were introduced into China by P&G in 2014, and then domestic brands successively increased their weight and launched multi cavity clotting beads integrating washing and nursing. The research shows that the main purchase channels of this kind of independently packaged concentrated washing and nursing products are concentrated online, and the main consumers are young people. According to the data, the post-90s are the main consumers of laundry beads, accounting for more than 50%, of which the 90-95 accounts for the highest proportion, accounting for 32%, and the post-95 accounts for 23%. On the whole, the laundry beads have the advantages of convenience and quickness, and they have a strong appeal to the young generation. In addition, the young generation has a strong ability to accept new things faster, so the laundry beads are mainly young people at present. It is expected that with the continuous penetration of laundry beads, it is expected to be popularized to all ages.

The Research Report on the Market Operation Situation and Investment Strategy of China’s Laundry Coagulation Industry from 2022 to 2027 released by Huajing Industry Research Institute pointed out that the year 2020, when the epidemic broke out, was a good opportunity for the development of laundry beads. The turnover of a brand on the e-commerce platform exceeded 100 million, with a year-on-year growth rate of more than 200%. For manufacturers, concentrated laundry beads are very profitable, even saving 7% of the packaging cost and 4.2% of the freight. It can be seen that there is still a large market penetration space for laundry beads. With the rising consumer awareness and acceptance, laundry beads are expected to become the main force in the future laundry market.

With the increasing expansion of the laundry bead market, the demand for its automated packaging has become increasingly strong. Hengli Packaging is fully capable of helping this type of product innovate its packaging form and improve its packaging level by relying on its own technical advantages when receiving inquiries from relevant customers.

02

Necessity of Automatic Packaging of Laundry Coagulation Beads with Intelligent Counting Equipmen

- Market development potential not to be underestimated

Through the analysis of a series of development processes after the coagulating beads bag officially entered the Chinese market, it can be seen that its light, fast and powerful cleaning ability has been favored by more and more young consumers, and it also has a trend of gradually penetrating into the whole age group. In order to meet the order demand of higher output, more and more enterprises begin to choose automated packaging instead of manual production.

- The Mature Development of Automatic Packaging Technology

Relying on the rich experience accumulated by Hengli Packaging in the automatic packaging industry for more than ten years, the technology has become quite mature in the face of the automatic packaging demand for products such as bead packs. In the actual packaging process, the automatic counting equipment of Hengli Packaging can accurately identify and package products of any shape, material and size. Compared with manual picking, the fully automated packaging production line can greatly improve efficiency and save labor costs, making packaging easier and more convenient.

03

Difficulties in automatic packaging for beads

The coagulating bead bag is used to wrap the concentrated laundry detergent with a water-soluble polymer material, which is as tough as plastic at room temperature and convenient for transportation and storage. The shape and texture of the beading bag have been determined, but due to its special shape, it needs to be accurately identified with customized solutions. Hengli Packaging can effectively solve such problems through its own professional technology. In addition, some customers put forward the concept of mixed packaging, which can also realize the complete packaging process from initial material handling to end sealing and palletizing through multiple automatic particle counting equipment. No matter the different packaging forms of cartoning, bagging or canning, they can also be flexibly adjusted to achieve the goal in one step.

04

Advantages of introducing intelligent counting equipment for automatic packaging for bead packs

- Fully automatic production line, human-computer interaction page setting, parameter storage, simple and fast

- Intelligent production management system, fast speed and high efficiency, effectively improving productivity

- Multi level vibration track, which can adjust the vibration level at any time to ensure that the product will not be damaged

- Flexible to adapt to products of various sizes and shapes, and any packaging form can meet