Intelligent electronic equipment packaging – Industrial products

For industrial parts of different sizes and shapes, Hengli Packaging can also achieve accurate mixing and easy packaging

Intelligent electronic equipment

packaging — industrial products

For industrial parts of different sizes and shapes, Hengli Packaging can also achieve accurate mixing and easy packaging

01

Market analysis of industrial parts packaging

- For all kinds of industrial parts, sorting and packaging play an important role. The public’s impression of parts may be ordinary screws, nuts, etc. Most of them have different shapes and are small in size. But in addition, there are many larger parts that also need to be uniformly stored and packaged, such as Lego building block toys popular among children, building blocks in various collage combination forms, etc. Don’t forget the existence of such insignificant but important buttons, because they also belong to the category of parts. The above part styles will be more complex, but their packaging needs are also huge.

- In any case, it is worth noting that since all kinds of parts can be seen everywhere in our lives, there is also a broad market for their collection and packaging.

02

Necessity of introducing intelligent electronic equipment to pack industrial products

- Particularity of parts

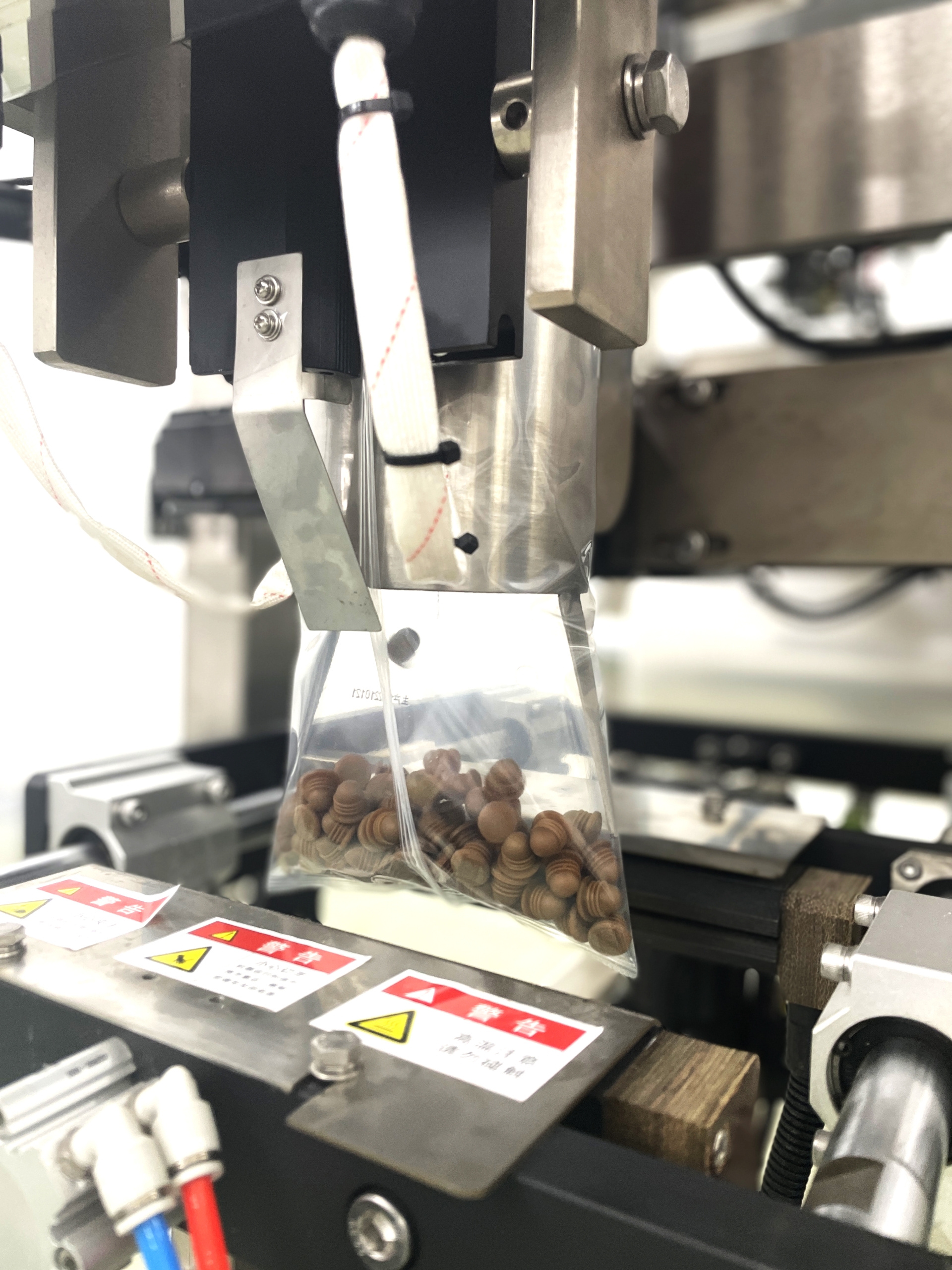

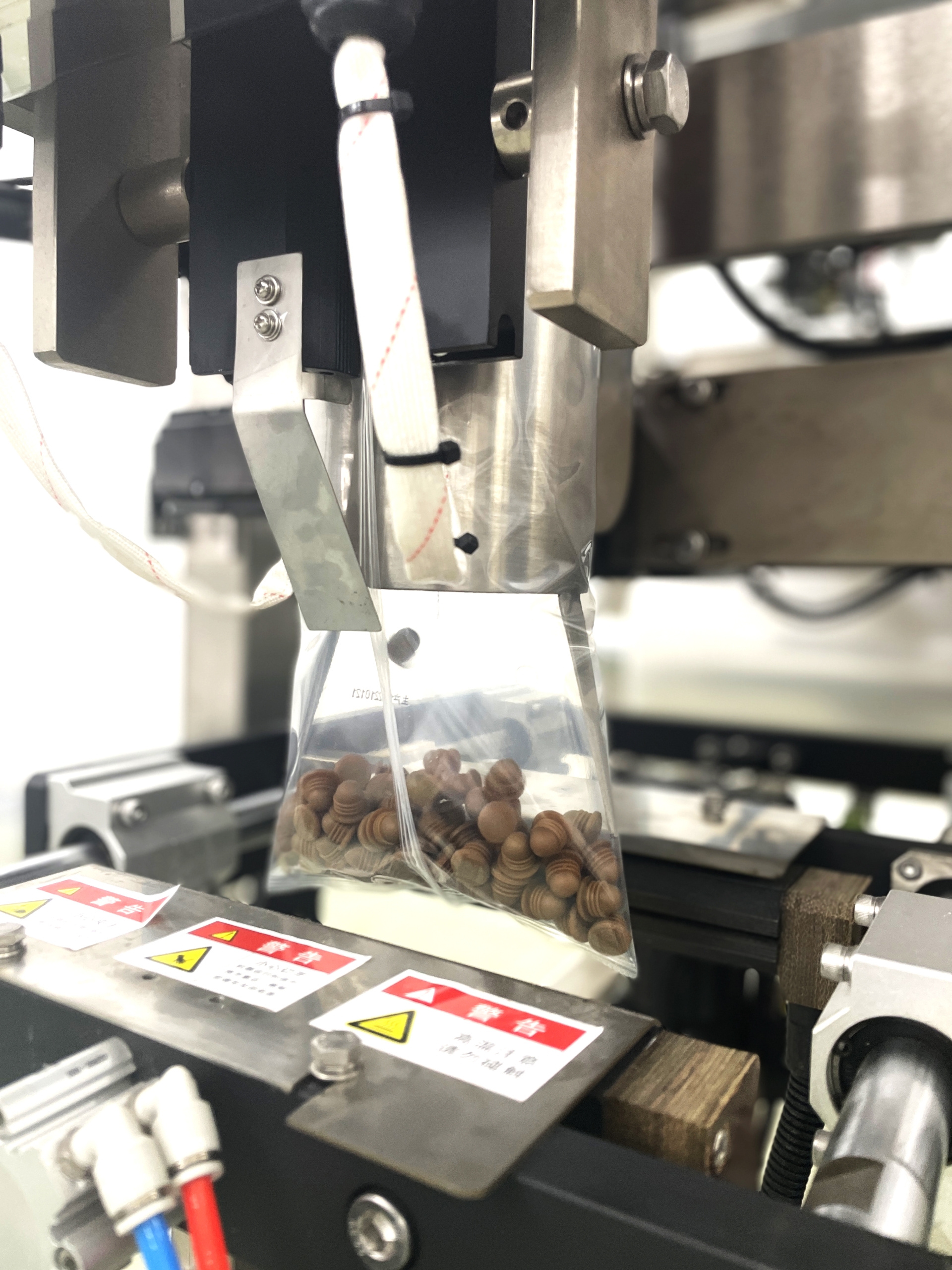

Industrial parts are generally numerous, small in size, and not the same type of parts for collection and packaging. In most cases, mixed packaging is the main method. In view of these special circumstances, if we still use the manual ancient mode to pick up and classify packaging, it will cost a huge amount of manpower, material resources and financial resources, and there may be various security risks and hidden dangers. The emergence of intelligent electronic multi granule device is to solve the problem and realize the freedom of packaging.

- Maturity of Hengli Packaging’s intelligent electronic counting technology

Since its establishment, Hengli Packaging has accumulated rich experience in intelligent electronic counting technology, and has been trying to promote this technology in all walks of life. Take buttons for example. They have different shapes, sizes, and materials. However, for several pieces of equipment handed to Hengli Packaging, you only need to set parameters on the human-computer interaction page, and photoelectric eye scanning will automatically identify the form. Whether it is a single type of packaging or a mixed packaging, it can be easily done.

02

Necessity of introducing intelligent electronic equipment to pack industrial products

- Particularity of parts

Industrial parts are generally numerous, small in size, and not the same type of parts for collection and packaging. In most cases, mixed packaging is the main method. In view of these special circumstances, if we still use the manual ancient mode to pick up and classify packaging, it will cost a huge amount of manpower, material resources and financial resources, and there may be various security risks and hidden dangers. The emergence of intelligent electronic multi granule device is to solve the problem and realize the freedom of packaging. - Maturity of Hengli Packaging’s intelligent electronic counting technology

Since its establishment, Hengli Packaging has accumulated rich experience in intelligent electronic counting technology, and has been trying to promote this technology in all walks of life. Take buttons for example. They have different shapes, sizes, and materials. However, for several pieces of equipment handed to Hengli Packaging, you only need to set parameters on the human-computer interaction page, and photoelectric eye scanning will automatically identify the form. Whether it is a single type of packaging or a mixed packaging, it can be easily done.

03

Difficulties in automated packaging for industrial products

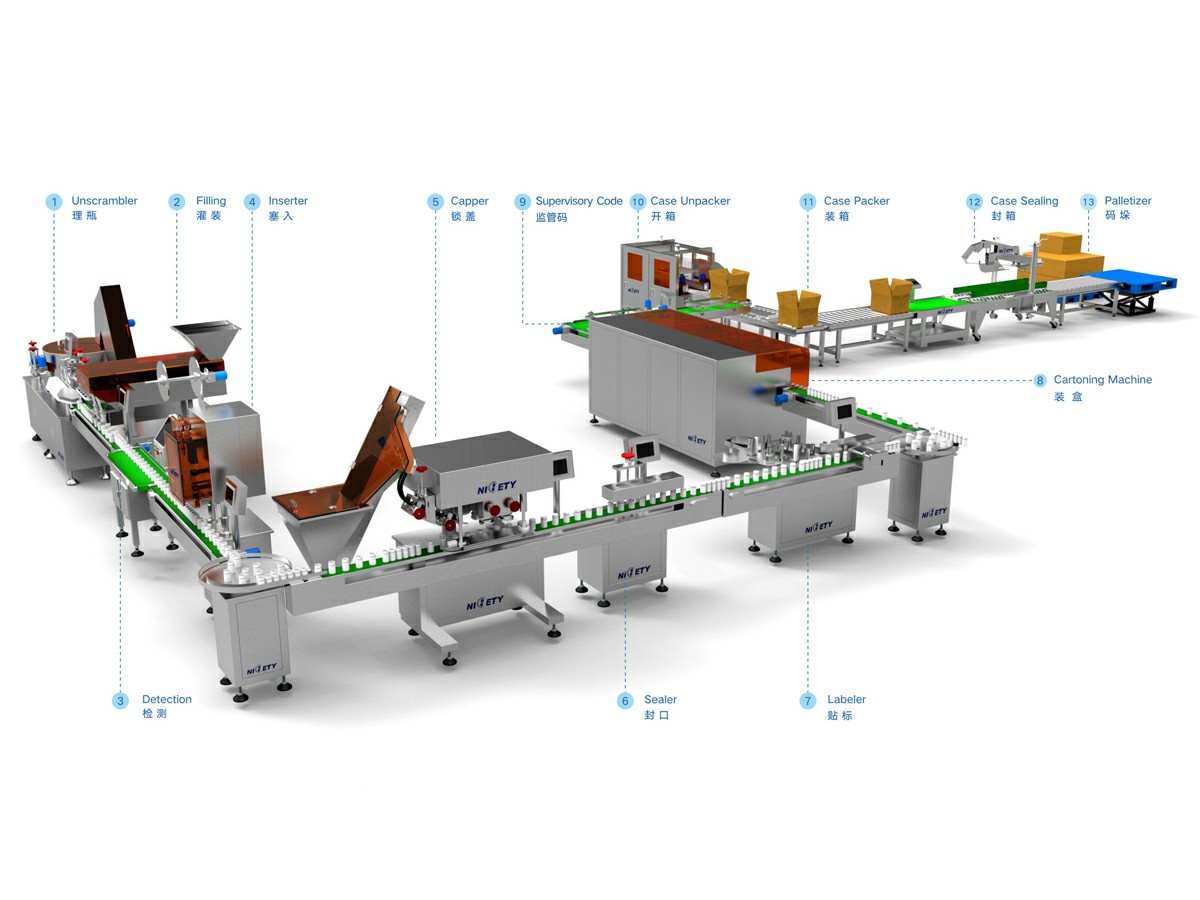

The industrial products mentioned above cover a wide range of fields, such as starting shells, Lego parts, plastic cans… They have various shapes, large and small volumes, and both soft and hard materials. This requires that the equipment for automatic packaging has a high degree of flexibility and adaptability. Hengli Packaging can easily meet the above requirements, implement the guideline of “everything can be counted, everything can be loaded”, solve problems from the source through personalized customization solutions and considerate whole process services, and can also connect with the front and rear end equipment to form a whole packaging production line, improve quality and efficiency, and achieve good and fast packaging.

04

Advantages of introducing intelligent electronic equipment to pack industrial products

- Human computer interaction page setting, parameter storage, intelligent operation, simple and fast

- Intelligent production management system, fast speed and high efficiency, effectively improving productivity

- Photoeye scanning identification, multi-level vibration track, ensuring accuracy

- Flexible to adapt to products of various sizes and shapes, and any packaging form can meet

03

Advantages of introducing intelligent electronic equipment to pack industrial products

- Human computer interaction page setting, parameter storage, intelligent operation, simple and fast

- Intelligent production management system, fast speed and high efficiency, effectively improving productivity

- Photoeye scanning identification, multi-level vibration track, ensuring accuracy

- Flexible to adapt to products of various sizes and shapes, and any packaging form can meet

Intelligent electronic equipment packaging industrial products

For industrial parts of different sizes and shapes, Hengli Packaging can also achieve accurate mixing and easy packaging

Intelligent electronic equipment packaging industrial products

For industrial parts of different sizes and shapes, Hengli Packaging can also achieve accurate mixing and easy packaging

01

Market analysis of industrial parts packaging

- For all kinds of industrial parts, sorting and packaging play an important role. The public’s impression of parts may be ordinary screws, nuts, etc. Most of them have different shapes and are small in size. But in addition, there are many larger parts that also need to be uniformly stored and packaged, such as Lego building block toys popular among children, building blocks in various collage combination forms, etc. Don’t forget the existence of such insignificant but important buttons, because they also belong to the category of parts. The above part styles will be more complex, but their packaging needs are also huge.

- In any case, it is worth noting that since all kinds of parts can be seen everywhere in our lives, there is also a broad market for their collection and packaging.

02

Necessity of introducing intelligent electronic equipment to pack industrial products

- Particularity of parts

Industrial parts are generally numerous, small in size, and not the same type of parts for collection and packaging. In most cases, mixed packaging is the main method. In view of these special circumstances, if we still use the manual ancient mode to pick up and classify packaging, it will cost a huge amount of manpower, material resources and financial resources, and there may be various security risks and hidden dangers. The emergence of intelligent electronic multi granule device is to solve the problem and realize the freedom of packaging. - Maturity of Hengli Packaging’s intelligent electronic counting technology

Since its establishment, Hengli Packaging has accumulated rich experience in intelligent electronic counting technology, and has been trying to promote this technology in all walks of life. Take buttons for example. They have different shapes, sizes, and materials. However, for several pieces of equipment handed to Hengli Packaging, you only need to set parameters on the human-computer interaction page, and photoelectric eye scanning will automatically identify the form. Whether it is a single type of packaging or a mixed packaging, it can be easily done.

02

Necessity of introducing intelligent electronic equipment to pack industrial products

- Particularity of parts

Industrial parts are generally numerous, small in size, and not the same type of parts for collection and packaging. In most cases, mixed packaging is the main method. In view of these special circumstances, if we still use the manual ancient mode to pick up and classify packaging, it will cost a huge amount of manpower, material resources and financial resources, and there may be various security risks and hidden dangers. The emergence of intelligent electronic multi granule device is to solve the problem and realize the freedom of packaging.

- Maturity of Hengli Packaging’s intelligent electronic counting technology

Since its establishment, Hengli Packaging has accumulated rich experience in intelligent electronic counting technology, and has been trying to promote this technology in all walks of life. Take buttons for example. They have different shapes, sizes, and materials. However, for several pieces of equipment handed to Hengli Packaging, you only need to set parameters on the human-computer interaction page, and photoelectric eye scanning will automatically identify the form. Whether it is a single type of packaging or a mixed packaging, it can be easily done.

03

Difficulties in automated packaging for industrial products

The industrial products mentioned above cover a wide range of fields, such as starting shells, Lego parts, plastic cans… They have various shapes, large and small volumes, and both soft and hard materials. This requires that the equipment for automatic packaging has a high degree of flexibility and adaptability. Hengli Packaging can easily meet the above requirements, implement the guideline of “everything can be counted, everything can be loaded”, solve problems from the source through personalized customization solutions and considerate whole process services, and can also connect with the front and rear end equipment to form a whole packaging production line, improve quality and efficiency, and achieve good and fast packaging.

04

Advantages of introducing intelligent electronic equipment to pack industrial products

- Human computer interaction page setting, parameter storage, intelligent operation, simple and fast

- Intelligent production management system, fast speed and high efficiency, effectively improving productivity

- Photoeye scanning identification, multi-level vibration track, ensuring accuracy

- Flexible to adapt to products of various sizes and shapes, and any packaging form can meet

03

Difficulties in automated packaging for industrial products

The industrial products mentioned above cover a wide range of fields, such as starting shells, Lego parts, plastic cans… They have various shapes, large and small volumes, and both soft and hard materials. This requires that the equipment for automatic packaging has a high degree of flexibility and adaptability. Hengli Packaging can easily meet the above requirements, implement the guideline of “everything can be counted, everything can be loaded”, solve problems from the source through personalized customization solutions and considerate whole process services, and can also connect with the front and rear end equipment to form a whole packaging production line, improve quality and efficiency, and achieve good and fast packaging.

04

Advantages of introducing intelligent electronic equipment to pack industrial products

- Human computer interaction page setting, parameter storage, intelligent operation, simple and fast

- Intelligent production management system, fast speed and high efficiency, effectively improving productivity

- Photoeye scanning identification, multi-level vibration track, ensuring accuracy

- Flexible to adapt to products of various sizes and shapes, and any packaging form can meet