Intelligent electronic counting equipment packaging – FOOD FRESH

Hengli Packaging, based on the characteristics of fresh products, keeps the accuracy of several pieces of equipment at the forefront of the industry at the same time, which is sound, fast, safe and healthy

01

Market analysis of fresh products

- In recent years, the world has undergone tremendous changes due to the COVID-19, which is also reflected in the fresh food industry. In this era when wearing masks when going out has become the norm and people have to be cautious when going out to buy food, more and more people choose to place orders on takeout or fresh food platforms, pack by specially assigned persons, and deliver goods to their homes. This has become the daily habit of the young generation of consumers. According to statistics, during the epidemic period, daily excellent fresh food increased more than 3 times on a year-on-year basis; Dingdong can increase 40000 to 50000 new users every day, and the order volume has more than tripled compared with last month; The sales of JD.com fresh food increased more than four times year on year, and the sales of multipoint DMALL also doubled year on year.

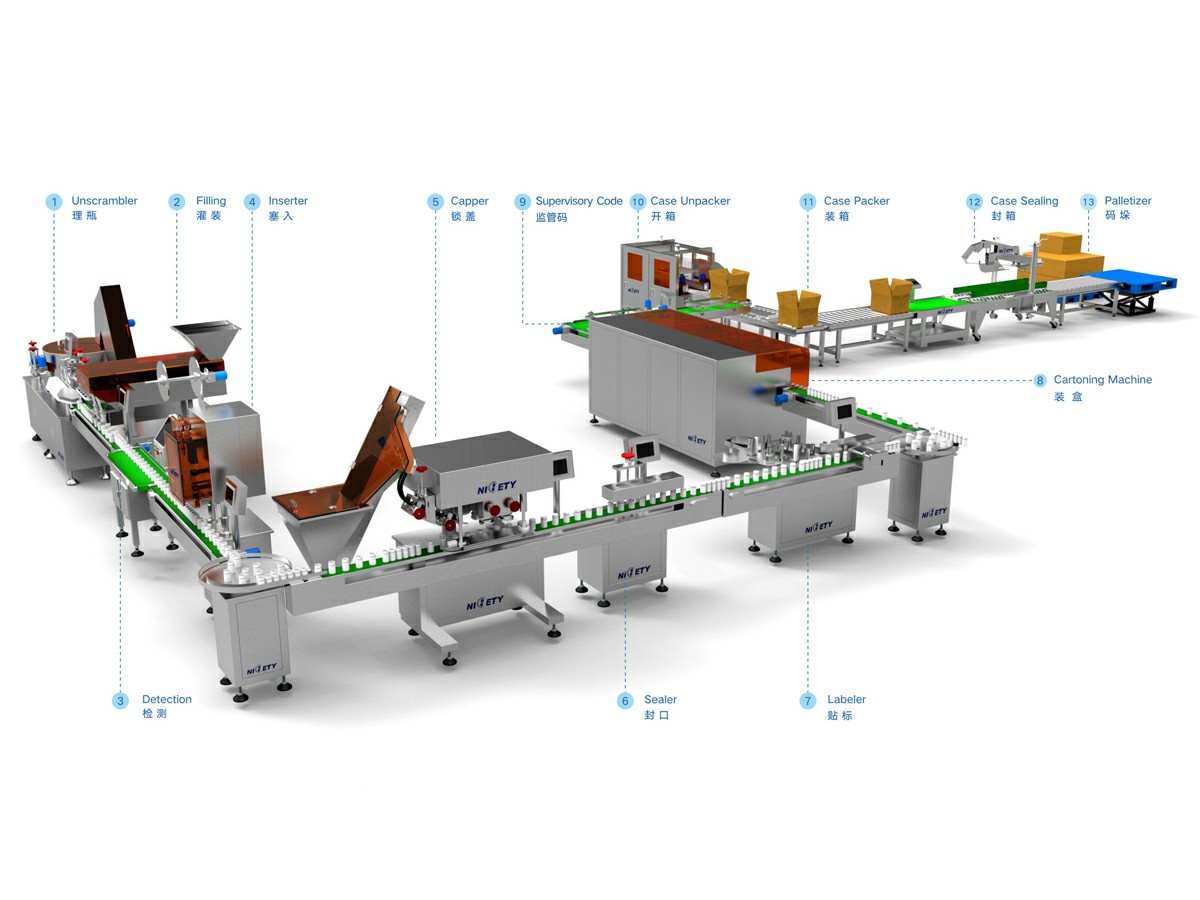

- With the rapid growth of fresh food online business, the requirements for commodity packaging will become more and more strict. Hengli Packaging introduces intelligent electronic packaging equipment to meet the packaging requirements of granular fresh fruits and vegetables, such as virgin fruits, so as to achieve a better and faster packaging of fresh products.

02

Necessity of introducing intelligent electronic counting equipment for packaging fresh food

- Speed requirements of the times

The special period mentioned above and the change of consumers’ shopping habits not only brought the fresh food platform back to life, but also put forward higher requirements for fresh food packaging. In the face of tens of thousands of orders every day, manual packaging naturally becomes unrealistic. The addition of intelligent automatic equipment can not only significantly improve the packaging speed, but also make the chaotic packaging process more orderly.

- The particularity of fresh food

It is well known that fresh food has very strict requirements on packaging due to its short shelf life. Too much human involvement may not only damage the freshness and state of the fruits and vegetables themselves, but also pose a great challenge to food safety. If intelligent electronic equipment is used for packaging in this regard, products of all shapes and sizes will achieve rapid and satisfactory packaging results.

- The intelligent automatic counting technology of Hengli Packaging is professional and reliable

As the core technical advantage of Hengli Packaging, the intelligent automatic counting packaging technology has been tested by time and different industries, and already has full experience in dealing with different types of products. When facing the counting packaging of fresh food, its flexibility and efficiency can fully meet the needs of different types of fresh food automatic packaging.

03

Difficulties in automatic packaging for fresh products

The two most important factors affecting the packaging of fresh products are environment and temperature. As we all know, fresh food is generally transported through the cold chain. If the safety and health of the production environment cannot be guaranteed as the first packaging link, everything will fall short. Based on years of experience in automated packaging, Hengli Packaging has studied thoroughly the packaging methods and specific requirements for fresh products, and is fully competent for efficient and orderly automated packaging under low temperature environment. The sorting system developed by Hengli Packaging can also realize rapid distribution, actively adapt to market rules, and help fresh food manufacturers win in the fierce competition.

04

Advantages of introducing intelligent electronic counting equipment for packaging fresh food

- Abandon the traditional packaging mode, help users reduce their dependence on labor and save costs

- Human computer interaction page setting, parameter storage, intelligent operation, simple and fast

- Intelligent production management system, fast speed and high efficiency, effectively improving productivity

- The equipment and materials meet the standard requirements of the food processing industry, and are safe and hygienic

Intelligent electronic counting equipment packaging food fresh

Hengli Packaging, based on the characteristics of fresh products, keeps the accuracy of several pieces of equipment at the forefront of the industry at the same time, which is sound, fast, safe and healthy

01

Market analysis of fresh products

- In recent years, the world has undergone tremendous changes due to the COVID-19, which is also reflected in the fresh food industry. In this era when wearing masks when going out has become the norm and people have to be cautious when going out to buy food, more and more people choose to place orders on takeout or fresh food platforms, pack by specially assigned persons, and deliver goods to their homes. This has become the daily habit of the young generation of consumers. According to statistics, during the epidemic period, daily excellent fresh food increased more than 3 times on a year-on-year basis; Dingdong can increase 40000 to 50000 new users every day, and the order volume has more than tripled compared with last month; The sales of JD.com fresh food increased more than four times year on year, and the sales of multipoint DMALL also doubled year on year.

- With the rapid growth of fresh food online business, the requirements for commodity packaging will become more and more strict. Hengli Packaging introduces intelligent electronic packaging equipment to meet the packaging requirements of granular fresh fruits and vegetables, such as virgin fruits, so as to achieve a better and faster packaging of fresh products.

02

Necessity of introducing intelligent electronic counting equipment for packaging fresh food

- Speed requirements of the times

The special period mentioned above and the change of consumers’ shopping habits not only brought the fresh food platform back to life, but also put forward higher requirements for fresh food packaging. In the face of tens of thousands of orders every day, manual packaging naturally becomes unrealistic. The addition of intelligent automatic equipment can not only significantly improve the packaging speed, but also make the chaotic packaging process more orderly.

- The particularity of fresh food

It is well known that fresh food has very strict requirements on packaging due to its short shelf life. Too much human involvement may not only damage the freshness and state of the fruits and vegetables themselves, but also pose a great challenge to food safety. If intelligent electronic equipment is used for packaging in this regard, products of all shapes and sizes will achieve rapid and satisfactory packaging results.

- The intelligent automatic counting technology of Hengli Packaging is professional and reliable

As the core technical advantage of Hengli Packaging, the intelligent automatic counting packaging technology has been tested by time and different industries, and already has full experience in dealing with different types of products. When facing the counting packaging of fresh food, its flexibility and efficiency can fully meet the needs of different types of fresh food automatic packaging.

03

Difficulties in automatic packaging for fresh products

The two most important factors affecting the packaging of fresh products are environment and temperature. As we all know, fresh food is generally transported through the cold chain. If the safety and health of the production environment cannot be guaranteed as the first packaging link, everything will fall short. Based on years of experience in automated packaging, Hengli Packaging has studied thoroughly the packaging methods and specific requirements for fresh products, and is fully competent for efficient and orderly automated packaging under low temperature environment. The sorting system developed by Hengli Packaging can also realize rapid distribution, actively adapt to market rules, and help fresh food manufacturers win in the fierce competition.

04

Advantages of introducing intelligent electronic counting equipment for packaging fresh food

- Abandon the traditional packaging mode, help users reduce their dependence on labor and save costs

- Human computer interaction page setting, parameter storage, intelligent operation, simple and fast

- Intelligent production management system, fast speed and high efficiency, effectively improving productivity

- The equipment and materials meet the standard requirements of the food processing industry, and are safe and hygienic