Intelligent electronic equipment packaging food – NUTS EVERY DAY

For the popular daily mixed packaging of nuts on the market, Hengli is based on the forefront of the industry. Each bag is delivered in a quantitative way, fast and efficient, while ensuring the integrity of the product form

01

Market analysis on daily nuts

- The COVID-19 has accelerated the transformation of people’s living habits, and the new trend of food consumption with “natural health” as the core is accelerating. A variety of outlets with the golden setting of “Delicacy and Nutrition” have been continuously created, among which the popularity is increasing. They are nutritious, crisp and crisp nuts. According to the 2021 Tmall Nuts Consumption Trend Report, in the fierce snack track, the market size of fried nuts is second only to pastries, ranking second in the consumption ranking.

- With the increase of entrants, the competition in nut market tends to be white hot. In 2015, Qingdao Wolong took the lead in launching the “Daily Nuts”, which successfully ignited the nut market. Since then, nut products have exploded, and the overall market size has increased by more than 500% annually. In fact, not only the daily nuts, but also the recently popular nut cereal and various nut gift boxes near the end of the year are all various branches of the category of nuts. It can be seen that there are huge consumers and market potential behind nuts.

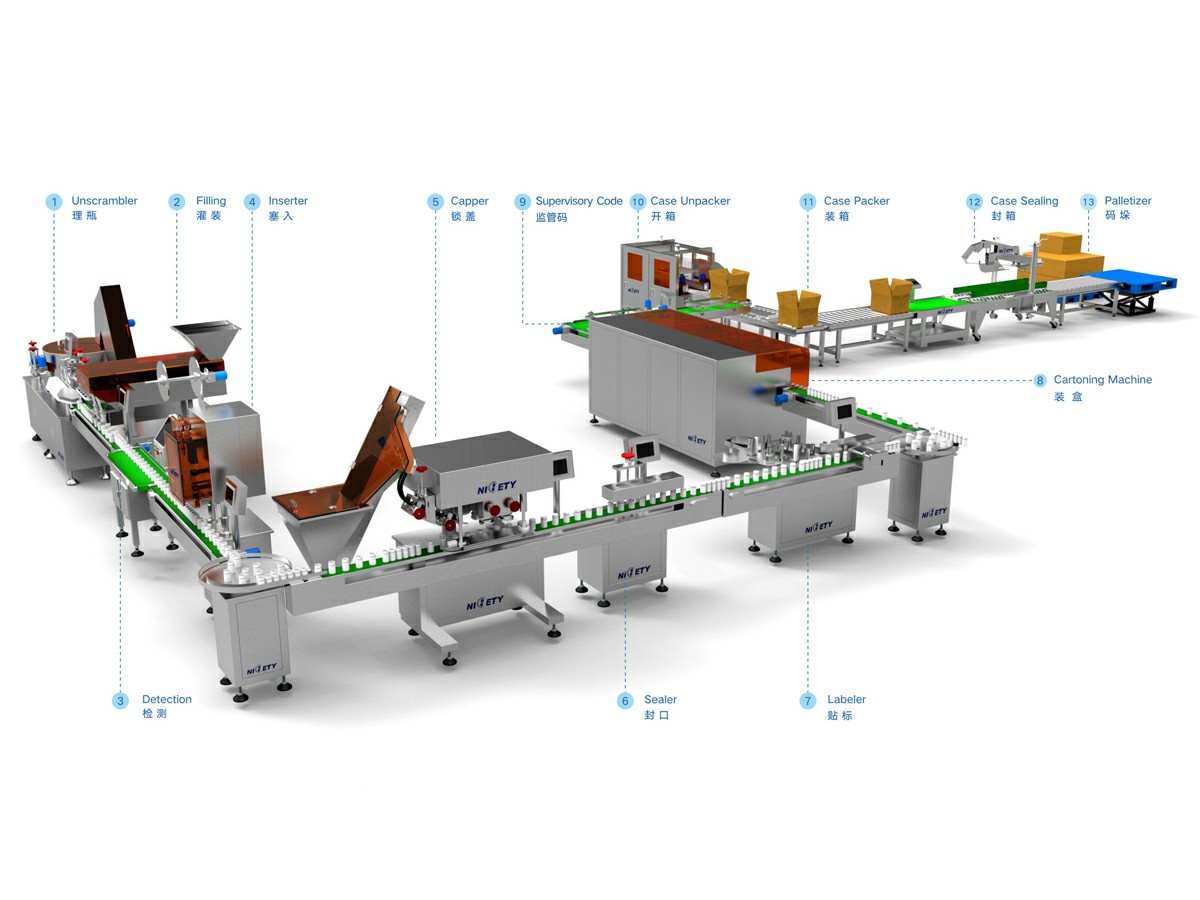

- For Hengli Packaging, the prevalence of such packaging forms as daily nuts just fits in with their understanding of the concept of mixed packaging. On the basis of improving the traditional weighing and counting packaging, the multi variety mixed packaging and counting equipment independently developed by the enterprise has introduced an intelligent system to help customers more easily in the process of product packaging.

02

Necessity of introducing automatic intelligent equipment to pack several nuts

- The obvious product convergence shows the importance of packaging form innovation

From the perspective of the product itself, the daily nut product does not have too much technical content and is highly reproducible, so the homogenization of daily nut products in the market is serious. Because of this, many enterprises entering the market will continue to innovate in product packaging, varieties, positioning and other aspects, and make corresponding nut combinations according to the nutritional needs of different populations to further subdivide the market. Frequent changes and innovations have gradually highlighted the advantages of intelligent production, and facts have proved that intelligent automatic packaging production is effective.

- The traditional weighing method has obvious defects

For the packaging method of daily nuts, which are packaged in bags, the uniform weighing method is usually used for filling. However, the traditional weighing mode is prone to errors in packaging, causing unnecessary losses to businesses. In addition, for ingredients that are wet and difficult to separate such as dried cranberries in daily nuts, weighing packaging method is also difficult to accurately measure and bag them.

- The introduction of intelligent technology increases the output and doubles the efficiency

The introduction of intelligence is to inject the light of science and technology into the packaging form to give the product a second life. Especially in the face of more complex mixed nut packaging production, the machine can identify and detect independently through the human-computer interaction screen, operate according to rules, and store parameters with one key, so that the whole process is safe, efficient and easy to understand while ensuring accuracy.

03

Difficulties in automatic packaging for daily nuts

The packaging form of daily nuts is special. Nuts and dried fruits are separated in one bag, which requires separating the dry and wet materials in advance during packaging. This is exactly the problem of automatic packaging of this type of products. Dried fruits are easy to stack and stick, and it is difficult to distinguish the different shapes of nuts when they are mixed together, but this can be easily done for Hengli Packaging. The above problems can be effectively solved by adjusting the vibration amplitude of corrugated boards and changing the track shape to better adapt to the material flow. In addition, compared with the speed of 3 packs/minute for manual packaging, the speed of Hengli packaging equipment is immediately increased by 1.5 times, which can reach 40 packs/minute.

04

Advantages of intelligent automatic counting technology in packaging various types of nuts

- Photoelectric scanning identification ensures filling accuracy, simple and efficient operation and saves labor

- Capable of mixed packaging of multiple varieties of nuts to meet the diversified needs of customers

- Multi stage vibrating track, separating ingredients from each other, and ensuring smooth and stable material transportation

- Equipment and materials meet the hygienic standards of food processing industry

Intelligent electronic equipment packaging food – uts every day

For the popular daily mixed packaging of nuts on the market, Hengli is based on the forefront of the industry. Each bag is delivered in a quantitative way, fast and efficient, while ensuring the integrity of the product form

01

Market analysis on daily nuts

- The COVID-19 has accelerated the transformation of people’s living habits, and the new trend of food consumption with “natural health” as the core is accelerating. A variety of outlets with the golden setting of “Delicacy and Nutrition” have been continuously created, among which the popularity is increasing. They are nutritious, crisp and crisp nuts. According to the 2021 Tmall Nuts Consumption Trend Report, in the fierce snack track, the market size of fried nuts is second only to pastries, ranking second in the consumption ranking.

- With the increase of entrants, the competition in nut market tends to be white hot. In 2015, Qingdao Wolong took the lead in launching the “Daily Nuts”, which successfully ignited the nut market. Since then, nut products have exploded, and the overall market size has increased by more than 500% annually. In fact, not only the daily nuts, but also the recently popular nut cereal and various nut gift boxes near the end of the year are all various branches of the category of nuts. It can be seen that there are huge consumers and market potential behind nuts.

- For Hengli Packaging, the prevalence of such packaging forms as daily nuts just fits in with their understanding of the concept of mixed packaging. On the basis of improving the traditional weighing and counting packaging, the multi variety mixed packaging and counting equipment independently developed by the enterprise has introduced an intelligent system to help customers more easily in the process of product packaging.

02

Necessity of introducing automatic intelligent equipment to pack several nuts

- The obvious product convergence shows the importance of packaging form innovation

From the perspective of the product itself, the daily nut product does not have too much technical content and is highly reproducible, so the homogenization of daily nut products in the market is serious. Because of this, many enterprises entering the market will continue to innovate in product packaging, varieties, positioning and other aspects, and make corresponding nut combinations according to the nutritional needs of different populations to further subdivide the market. Frequent changes and innovations have gradually highlighted the advantages of intelligent production, and facts have proved that intelligent automatic packaging production is effective.

- The traditional weighing method has obvious defects

For the packaging method of daily nuts, which are packaged in bags, the uniform weighing method is usually used for filling. However, the traditional weighing mode is prone to errors in packaging, causing unnecessary losses to businesses. In addition, for ingredients that are wet and difficult to separate such as dried cranberries in daily nuts, weighing packaging method is also difficult to accurately measure and bag them.

- The introduction of intelligent technology increases the output and doubles the efficiency

The introduction of intelligence is to inject the light of science and technology into the packaging form to give the product a second life. Especially in the face of more complex mixed nut packaging production, the machine can identify and detect independently through the human-computer interaction screen, operate according to rules, and store parameters with one key, so that the whole process is safe, efficient and easy to understand while ensuring accuracy.

03

Difficulties in automatic packaging for daily nuts

The packaging form of daily nuts is special. Nuts and dried fruits are separated in one bag, which requires separating the dry and wet materials in advance during packaging. This is exactly the problem of automatic packaging of this type of products. Dried fruits are easy to stack and stick, and it is difficult to distinguish the different shapes of nuts when they are mixed together, but this can be easily done for Hengli Packaging. The above problems can be effectively solved by adjusting the vibration amplitude of corrugated boards and changing the track shape to better adapt to the material flow. In addition, compared with the speed of 3 packs/minute for manual packaging, the speed of Hengli packaging equipment is immediately increased by 1.5 times, which can reach 40 packs/minute.

04

Advantages of intelligent automatic counting technology in packaging various types of nuts

- Photoelectric scanning identification ensures filling accuracy, simple and efficient operation and saves labor

- Capable of mixed packaging of multiple varieties of nuts to meet the diversified needs of customers

- Multi stage vibrating track, separating ingredients from each other, and ensuring smooth and stable material transportation

- Equipment and materials meet the hygienic standards of food processing industry