Intelligent counting equipment packaging for gummies

Since the gummies are becoming more and more popular, many companies choose the intelligent counting equipments to make packaging easier and more convenient

01

Market Analysis for Gummy Products

- Functional food is new in China. With the growing demand for health care among young people, “functional leisure food and health food” has become a fashion. In the past two years, with the rising of “functionality ”, meaning health, fun, beauty, convenience and other characteristics, the world has opened a breakthrough among the young peple for gummies, providing a convenient possibility for health care at any time and anywhere in multiple scenarios, making health care “quick digestion”.

- According to other data, the global sales of functional food will exceed 8.6 billion dollars in 2022, and the domestic market demand for fudge will also show a rapid increase. The soft gummy industry has caught the customers’ eyes because of its innovative entry of “functionality”. This powerful booster has provided a historic development opportunity for the industry.

- For Hengli Packaging, the popularity of soft candy has led to more diversified packaging methods, and the market demand has become huge. The counting and bagging packaging machine specially developed by Hengli Packaging can meet all kinds of packaging needs by using intelligent packaging production mode.

02

Necessity of introducing intelligent equipment for automatic packaging for Gummies

- Market demand

Soft candy attracts a large amount of capital, which brings huge demand while increasing market attention. In view of this, the conventional manual packaging is obviously not enough to support the production capacity. If the early marketing publicity plan is complete, the later production packaging will fall shorter due to the lower packaging efficiency.

- Safety problems in packaging production

With the improvement of the safety and health standards of the food industry in recent years, the defects of the original manual packaging have become more and more obvious. It can be seen that there are too many unstable factors in the production of manual packaging. If machine production equipment is used to replace labor, not only food safety can be guaranteed, but also a lot of expenses incurred by employing labor can be saved.

- Maturity of intelligent packaging technology

The electronic counting technology is widely used in the pharmaceutical industry, and all kinds of counting packages have strict requirements. Now, Hengli Packaging introduces this technology into the food field, with its advantages of convenience, easy operation, cost saving, and effective avoidance of human risks, to use a more relaxed way to obtain greater benefits.

03

Difficulties in automatic packaging for Gummy

There are two packaging forms for soft candy. First, the naked sugar is directly counted and then bagged, bottled and canned. Due to the special properties of fudge, it is sensitive of temperature, and the surface is easy to produce viscosity, which makes it difficult to count automatically. The automation equipment of Hengli Packaging has accumulated full experience in dealing with these problems. It ensures the flow of naked sugar on the counting channel by adjusting the amplitude and relevant parameters. The other is to put the packaged pillow shaped soft candy into large bags. Whether it is required to count accurately or weigh the package, Hengli Packaging can meet customer requirements and help customers improve their packaging level and competitiveness in the market.

04

Advantages of intelligent automatic packaging for Gummy

- Intelligent production management system to effectively improve production capacity

- Help users reduce their dependence on labor and greatly save costs

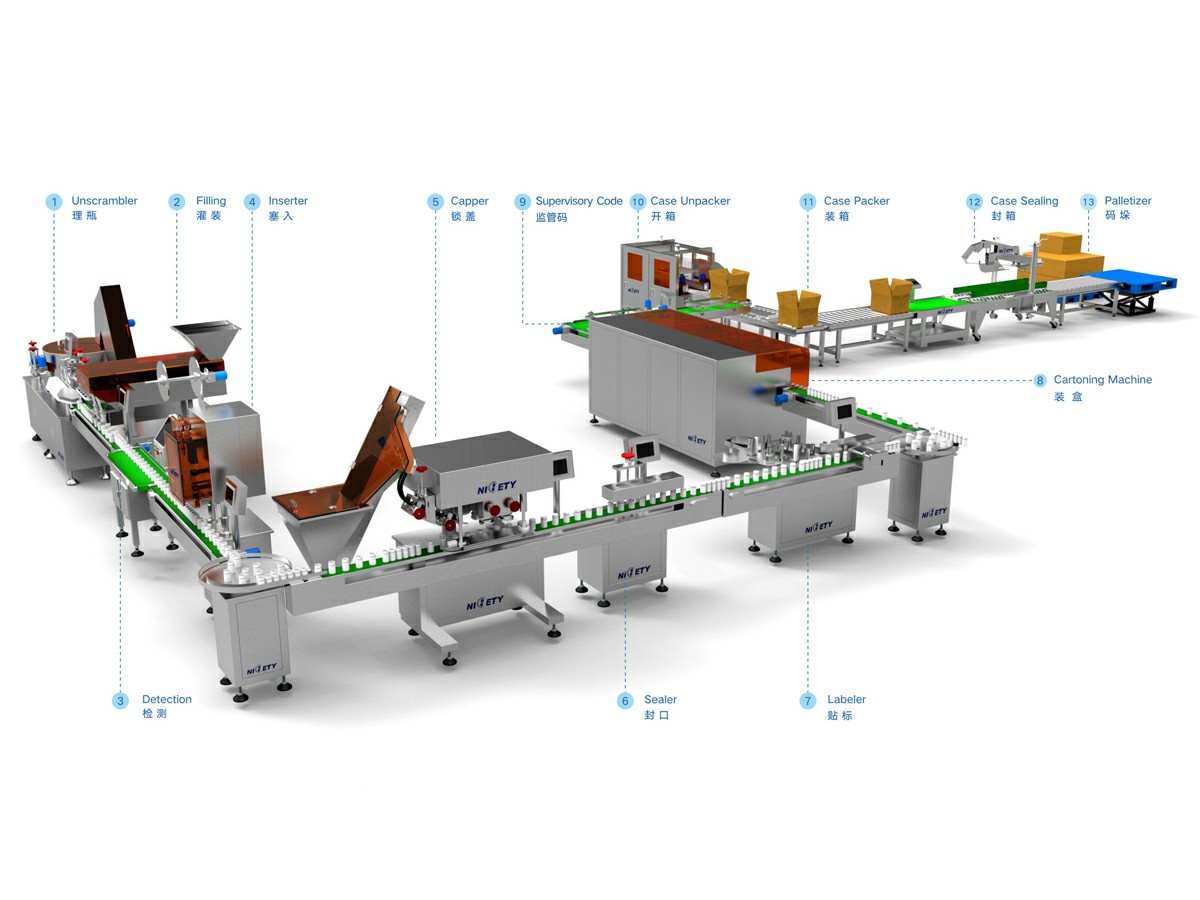

- Each link of packaging is closely linked, with accurate counting, saving time and effort

- Soft candy products that can flexibly adapt to various sizes, shapes and textures, and meet diversified packaging forms

RECOMMENDED CASES

Intelligent counting equipment

packaging for gummies

Since the gummies are becoming more and more popular, many companies choose the intelligent counting equipments to make packaging easier and more convenient

01

Market Analysis for Gummy Products

- Functional food is new in China. With the growing demand for health care among young people, “functional leisure food and health food” has become a fashion. In the past two years, with the rising of “functionality ”, meaning health, fun, beauty, convenience and other characteristics, the world has opened a breakthrough among the young peple for gummies, providing a convenient possibility for health care at any time and anywhere in multiple scenarios, making health care “quick digestion”.

- According to other data, the global sales of functional food will exceed 8.6 billion dollars in 2022, and the domestic market demand for fudge will also show a rapid increase. The soft gummy industry has caught the customers’ eyes because of its innovative entry of “functionality”. This powerful booster has provided a historic development opportunity for the industry.

- For Hengli Packaging, the popularity of soft candy has led to more diversified packaging methods, and the market demand has become huge. The counting and bagging packaging machine specially developed by Hengli Packaging can meet all kinds of packaging needs by using intelligent packaging production mode.

02

Necessity of introducing intelligent equipment for automatic packaging for Gummies

- Market demand

Soft candy attracts a large amount of capital, which brings huge demand while increasing market attention. In view of this, the conventional manual packaging is obviously not enough to support the production capacity. If the early marketing publicity plan is complete, the later production packaging will fall shorter due to the lower packaging efficiency. - Safety problems in packaging production

With the improvement of the safety and health standards of the food industry in recent years, the defects of the original manual packaging have become more and more obvious. It can be seen that there are too many unstable factors in the production of manual packaging. If machine production equipment is used to replace labor, not only food safety can be guaranteed, but also a lot of expenses incurred by employing labor can be saved. - Maturity of intelligent packaging technology

The electronic counting technology is widely used in the pharmaceutical industry, and all kinds of counting packages have strict requirements. Now, Hengli Packaging introduces this technology into the food field, with its advantages of convenience, easy operation, cost saving, and effective avoidance of human risks, to use a more relaxed way to obtain greater benefits.

03

Difficulties in automatic packaging for Gummy

There are two packaging forms for soft candy. First, the naked sugar is directly counted and then bagged, bottled and canned. Due to the special properties of fudge, it is sensitive of temperature, and the surface is easy to produce viscosity, which makes it difficult to count automatically. The automation equipment of Hengli Packaging has accumulated full experience in dealing with these problems. It ensures the flow of naked sugar on the counting channel by adjusting the amplitude and relevant parameters. The other is to put the packaged pillow shaped soft candy into large bags. Whether it is required to count accurately or weigh the package, Hengli Packaging can meet customer requirements and help customers improve their packaging level and competitiveness in the market.

04

Advantages of intelligent automatic packaging for Gummy

- Intelligent production management system to effectively improve production capacity

- Help users reduce their dependence on labor and greatly save costs

- Each link of packaging is closely linked, with accurate counting, saving time and effort

- Soft candy products that can flexibly adapt to various sizes, shapes and textures, and meet diversified packaging forms